Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Precision in Progress: Louis Machine’s CNC Prototypes

Computer Numerical Control (CNC) technology has revolutionized modern manufacturing by automating processes through precise computer instructions. By translating digital designs into physical products with unparalleled accuracy, CNC machining ensures high precision, efficiency, and stability in production. At the forefront of CNC prototyping stands Louis Machine, a pioneering innovator renowned for its commitment to excellence. With state-of-the-art equipment and expertise, Louis Machine delivers customized parts and components tailored to meet diverse requirements. Whether intricate or large-scale, Louis Machine guarantees exceptional quality, reliability, and adherence to client specifications. Embracing cutting-edge technology, Louis Machine continues to redefine the standards of precision engineering, offering unparalleled solutions in the dynamic landscape of modern manufacturing.

From Concept to Prototype: The CNC Prototyping Process at Louis Machine

Conceptualization and Design

Louis Machine initiates the CNC prototyping process by collaborating closely with clients to understand their unique requirements. Leveraging cutting-edge design software, our team transforms concepts into comprehensive 2D and 3D designs, ensuring precise visualization and feasibility assessment.

Programming

Once the design is finalized, skilled engineers at Louis Machine meticulously program CNC machines to execute the manufacturing process with unparalleled accuracy. Through advanced software integration, intricate geometries and specifications are translated into precise machine instructions.

Machining

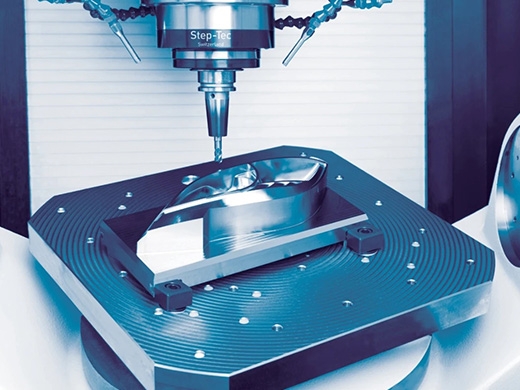

Equipped with state-of-the-art equipment from industry-leading brands such as ROEDERS, MAKINO, and SEIBU, Louis Machine executes CNC machining with exceptional precision. Our machinery boasts remarkable accuracy levels, reaching +/-0.002mm, ensuring that every component adheres to exact specifications.

Post-Processing and Quality Control

After machining, components undergo rigorous post-processing to refine surface finishes and dimensions. Louis Machine’s strong quality control department, equipped with Coordinate Measuring Machines (CMM) such as ZEISS and Hexagon, meticulously inspects each prototype to ensure adherence to stringent quality standards.

Precision and Accuracy

Precision and accuracy are paramount throughout the CNC prototyping process at Louis Machine. From initial design to final inspection, meticulous attention is paid to every detail to achieve the highest levels of precision. Our commitment to excellence enables us to troubleshoot complex issues such as warpage and weld lines, ensuring the flawless execution of even the most intricate designs.

Louis Machine’s dedication to delivering on-time, premium-quality prototypes at competitive prices underscores our position as a leading innovator in CNC prototyping. With expertise spanning mold design, plastic injection, die casting, and hardware manufacture, we offer comprehensive solutions tailored to meet the diverse needs of our clients.

Materials and Technologies

Materials in CNC Prototyping

Louis Machine utilizes a diverse range of materials tailored to meet the requirements of each project. Commonly used materials include metals such as aluminum, steel, and titanium, renowned for their strength and durability. Additionally, we work with engineering plastics like ABS, nylon, and PEEK, prized for their versatility and thermal stability. Our extensive material selection ensures compatibility with various applications, from automotive parts to consumer electronics.

State-of-the-Art CNC Machines and Software

At Louis Machine, we employ cutting-edge CNC machines and software to achieve unparalleled precision and efficiency in prototyping. Our machinery includes high-performance models from renowned brands like ROEDERS, MAKINO, and SEIBU, renowned for their exceptional accuracy and reliability. Paired with advanced CAD/CAM software, such as SolidWorks and Mastercam, our engineers program intricate designs with ease, ensuring seamless translation into manufacturing instructions.

Innovations and Custom Solutions

Louis Machine prides itself on its ability to innovate and develop custom solutions to meet the unique needs of each project. Our team of skilled engineers collaborates closely with clients to understand their specific requirements and challenges, leveraging our expertise to devise innovative approaches. Whether it’s implementing advanced machining techniques, developing specialized tooling, or integrating novel materials, we go above and beyond to deliver tailored solutions that exceed expectations. From concept to completion, Louis Machine remains committed to pushing the boundaries of CNC prototyping to deliver exceptional results.

Application of CNC Prototyping

Automotive Industry

Within the automotive sector, CNC prototyping serves as a vital tool, expediting the development and testing phases of new vehicle components. Louis Machine’s specialization lies in crafting precise automotive parts, spanning from engine elements to interior trim details. Leveraging CNC machining techniques, we guarantee dimensional accuracy and impeccable finishes, contributing to the industry’s innovation and efficiency.

Consumer Electronics

The consumer electronics realm relies heavily on CNC prototyping to fashion intricate and exact components for gadgets like smartphones, laptops, and wearable devices. Louis Machine excels in working with diverse materials such as aluminum and engineering plastics, enabling us to fabricate tailored electronic enclosures, connectors, and other vital parts with unparalleled precision.

Medical Devices

In the sphere of medical technology, CNC prototyping assumes a pivotal role, prioritizing precision and dependability. Louis Machine boasts proficiency in machining biocompatible materials like titanium and medical-grade plastics, crafting components crucial for surgical instruments, implants, and diagnostic apparatuses. Our adherence to regulatory standards ensures the utmost quality and safety in medical device development.

Aerospace and Defense

The aerospace and defense industries demand CNC prototyping for manufacturing intricate components with rigorous tolerances and quality standards. Louis Machine’s advanced machining capabilities, coupled with our unwavering commitment to precision, position us as a trusted partner in producing aerospace components, missile parts, and defense equipment of superior quality and reliability.

Industrial Machinery

CNC prototyping holds significant sway in the fabrication of industrial machinery and equipment, where resilience and precision reign supreme. Louis Machine specializes in machining large-scale components and assemblies for industrial automation systems, manufacturing equipment, and heavy machinery. Our solutions adhere to the highest performance and durability standards, catering to the robust demands of industrial applications.

The Future of CNC Prototyping at Louis Machine

Anticipated Technological Advancements

Louis Machine anticipates several technological advancements that will shape the future of CNC prototyping. This includes advancements in machine learning and artificial intelligence, enabling predictive maintenance and optimization of machining processes. Additionally, the integration of additive manufacturing techniques with traditional CNC machining is expected to offer new possibilities for complex part fabrication. Enhanced precision and speed through the development of more advanced CNC controllers and tooling technologies are also on the horizon.

Potential Impact on CNC Prototyping

These technological advancements are poised to revolutionize CNC prototyping at Louis Machine, enhancing efficiency, precision, and flexibility. Predictive maintenance algorithms will minimize downtime and optimize machine utilization, leading to increased productivity and reduced costs. The integration of additive manufacturing will enable the production of highly complex parts with greater design freedom and reduced material waste. Advanced CNC controllers and tooling technologies will further improve the quality and accuracy of machined components, meeting the evolving needs of clients across various industries.

Louis Machine’s Vision for the Future

Louis Machine is committed to embracing these advancements and leading the way in the future of CNC prototyping. We envision continued investments in state-of-the-art technology, including the acquisition of advanced CNC machines and software systems. Comprehensive training programs will ensure our team remains at the forefront of industry trends and innovations. Process improvements will be implemented to streamline operations and further enhance quality and efficiency. By staying proactive and adaptable, Louis Machine aims to maintain its position as a trusted partner for precision engineering solutions, meeting the evolving needs of clients with excellence and innovation.

Partner with Louis Machine for Tomorrow’s Prototyping Needs!

In the dynamic landscape of modern manufacturing, precision is paramount, and Louis Machine stands at the forefront of CNC prototyping excellence. With a commitment to innovation, advanced technology, and unwavering dedication to quality, Louis Machine delivers precision-engineered prototypes that redefine industry standards. Anticipating and embracing technological advancements, we continuously strive to enhance efficiency, accuracy, and versatility in our processes. From automotive to aerospace, consumer electronics to medical devices, Louis Machine’s CNC prototypes epitomize precision in progress, empowering clients with superior solutions that meet the demands of tomorrow’s world.