Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Why is Clamping Fixture Essential in Modern Manufacturing?

Delve into the future trends of Clamping Fixture, including automation, advanced materials, and market expansion. Discover how Louis Machine pioneers sustainable and cutting-edge solutions for evolving manufacturing needs.

Understanding Clamping Fixture

What is a Clamping Fixture?

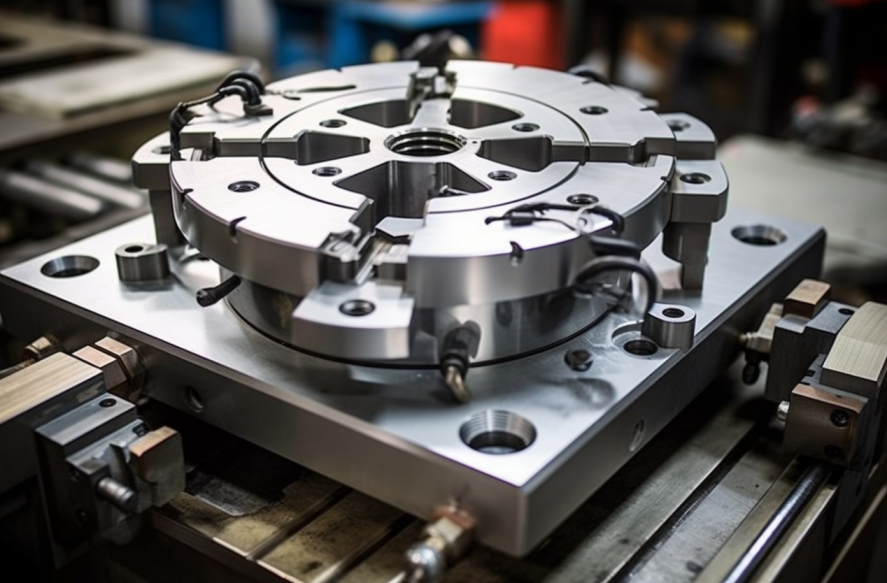

Clamping Fixture is specialized devices used in various manufacturing processes to hold workpieces securely in place. These fixtures ensure that the workpiece remains stationary and aligned during machining, welding, or assembly processes, which is crucial for achieving high precision and consistency. Clamping Fixture comes in different types and configurations, tailored to specific applications and requirements.

Definition and Function

A clamping fixture serves as a critical tool in manufacturing by providing a stable platform for workpieces. This stability is essential for precision operations, as any movement can lead to defects or inconsistencies. The main function of a clamping fixture is to secure the workpiece, preventing it from shifting under the forces applied during machining or assembly.

Types of Clamping Fixture

There are various types of Clamping Fixture, each designed for specific applications. Common types include manual clamps, pneumatic clamps, hydraulic clamps, and magnetic clamps. Each type offers unique advantages, such as speed, strength, and ease of use, making them suitable for different manufacturing environments.

Importance in Manufacturing

The use of Clamping Fixture is vital for achieving high-quality results in manufacturing. They help reduce errors, improve safety, and increase efficiency by holding workpieces firmly in place. Without proper Clamping Fixture, manufacturers would face difficulties in maintaining precision, leading to increased waste and higher production costs.

Market Status and Needs

Current Market Landscape

The market for Clamping Fixture is experiencing significant growth, driven by the demand for high precision and efficiency in manufacturing processes. Industries such as automotive, aerospace, electronics, and consumer goods are increasingly adopting advanced clamping solutions to enhance their production capabilities.

Market Growth

The global clamping fixture market is expanding due to technological advancements and the increasing complexity of manufacturing processes. As industries strive for higher accuracy and productivity, the need for reliable clamping solutions is more critical than ever. This growth is reflected in the rising investments in research and development of innovative clamping technologies.

Key Players

Leading companies in the clamping fixture market are continuously innovating to meet the evolving needs of manufacturers. These key players include Louis Machine, renowned for its state-of-the-art clamping solutions. Their products are known for their durability, precision, and adaptability, making them a preferred choice for various industrial applications.

Regional Demand

The demand for Clamping Fixture varies across regions, with North America, Europe, and Asia-Pacific being the primary markets. The rapid industrialization in Asia-Pacific, coupled with the increasing adoption of automation in manufacturing, is driving the demand for advanced Clamping Fixture. Meanwhile, established industries in North America and Europe continue to invest in high-quality fixtures to maintain their competitive edge.

Industry Challenges

Manufacturers face several challenges when it comes to implementing and utilizing Clamping Fixture. These challenges include the need for customization, ensuring compatibility with different machinery, and maintaining high precision in production.

Customization Needs

Each manufacturing process is unique, requiring Clamping Fixture to be tailored to specific applications. Customization can be challenging and time-consuming, as it involves designing fixtures that meet the exact specifications of the workpiece and the machinery used. Manufacturers need to work closely with fixture suppliers like Louis Machine to develop customized solutions that enhance productivity and precision.

Compatibility Issues

Ensuring that Clamping Fixture is compatible with different types of machinery is another challenge. Manufacturers often use a variety of machines in their production lines, and the fixtures must be adaptable to these diverse setups. This requires fixtures that are versatile and easily adjustable to fit different machine configurations.

Maintaining Precision

High precision is crucial in industries such as aerospace, automotive, and electronics. Clamping Fixture must hold the workpiece firmly without causing any deformation or misalignment. Achieving this level of precision requires high-quality materials and meticulous design, making it a complex and demanding task for manufacturers and suppliers.

Applications in Key Industries

Clamping Fixture is essential in several industries, including precision mold design and manufacturing, plastic injection molding production, metal hardware parts processing, and automotive parts manufacturing.

Precision Mold Design and Manufacturing

In precision mold design, Clamping Fixture ensures that mold components are held securely during the machining process. This is critical for achieving the exact dimensions and surface finish required for high-quality molds. Reliable Clamping Fixture likes those from Louis Machine play a vital role in maintaining the integrity of the molds, leading to better performance and longevity.

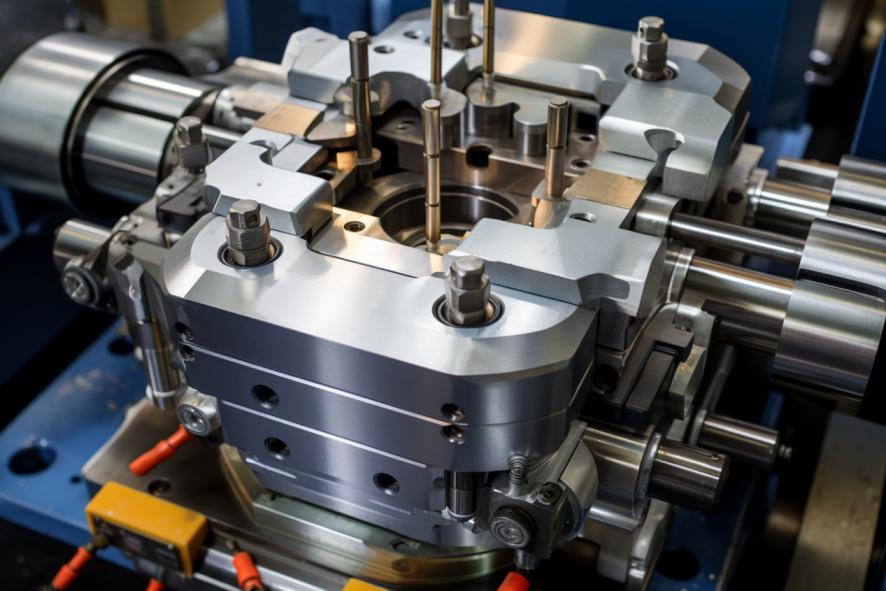

Plastic Injection Molding Production

Plastic injection molding requires precise control over the positioning of molds and inserts. Clamping Fixture helps achieve this by securing the molds in place during the injection process. This results in consistent and high-quality plastic parts, essential for industries such as consumer electronics and automotive.

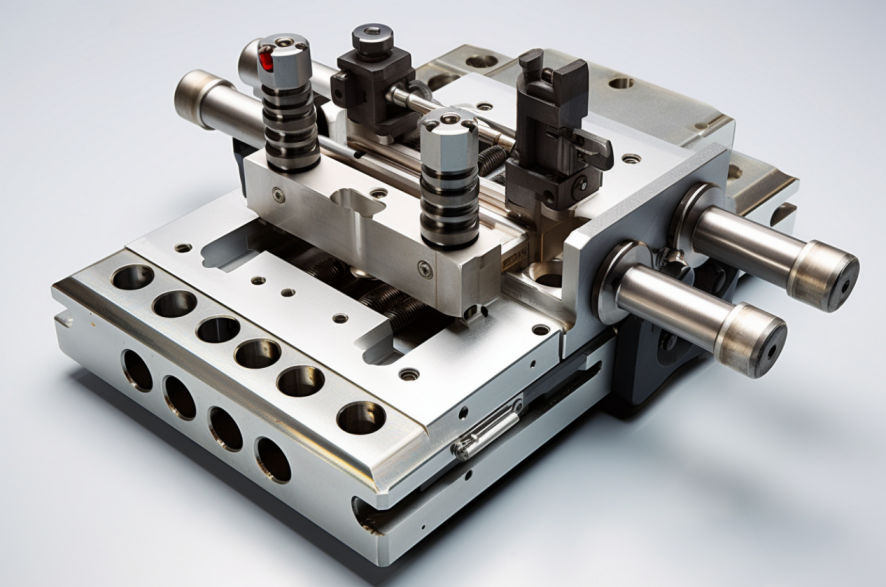

Metal Hardware Parts Processing

In the processing of metal hardware parts, Clamping Fixture ensures that the workpieces remain stable during machining operations such as drilling, milling, and grinding. This stability is crucial for producing parts with tight tolerances and high surface quality. Louis Machine’s advanced clamping solutions are widely used in this sector for their reliability and precision.

2024 Best Clamping Fixture Service: Louis Machine

Why Louis Machine?

Louis Machine stands out as the best clamping fixture service provider in 2024, offering innovative and high-quality solutions tailored to meet the diverse needs of various industries. Their commitment to excellence and customer satisfaction sets them apart from competitors.

Expertise and Experience

With years of experience in the industry, Louis Machine has developed a deep understanding of the challenges and requirements of different manufacturing processes. Their expertise allows them to design and produce Clamping Fixture that are not only effective but also durable and easy to use.

Innovative Solutions

Louis Machine continuously invests in research and development to bring innovative clamping solutions to the market. Their products incorporate the latest technologies and materials, ensuring high performance and reliability. Whether it’s for high-precision mold design or large-scale automotive parts manufacturing, Louis Machine offers solutions that enhance productivity and quality.

Customer Support

Customer satisfaction is a top priority for Louis Machine. They provide comprehensive support to their clients, from initial consultation and design to installation and maintenance. Their team of experts works closely with customers to ensure that the Clamping Fixture meets their specific needs and delivers optimal performance.

Features of Louis Machine Clamping Fixture

Louis Machine’s Clamping Fixture are designed to offer superior performance and reliability, making them the preferred choice for many manufacturers.

High Precision

Precision is a hallmark of Louis Machine’s Clamping Fixture. They are engineered to hold workpieces securely without causing any deformation or misalignment. This precision is essential for achieving high-quality results in manufacturing processes.

Durability

Constructed from high-quality materials, Louis Machine’s Clamping Fixture is built to withstand the rigors of industrial use. Their durability ensures long service life, reducing the need for frequent replacements and maintenance.

Versatility

Louis Machine offers a wide range of Clamping Fixture that can be adapted to different machines and applications. This versatility makes their products suitable for various industries, from aerospace to consumer goods.

Case Studies

Several companies have benefited from Louis Machine’s clamping fixture solutions, achieving significant improvements in their manufacturing processes.

Automotive Parts Manufacturing

A leading automotive parts manufacturer adopted Louis Machine’s Clamping Fixture to enhance the precision and efficiency of their production line. The result was a significant reduction in defects and an increase in production speed, leading to higher overall productivity.

Electronics Industry

In the electronics industry, a company specializing in consumer electronics used Louis Machine’s Clamping Fixture to improve the accuracy of their assembly processes. This led to better product quality and a reduction in assembly time, giving them a competitive edge in the market.

Aerospace Sector

An aerospace manufacturer implemented Louis Machine’s clamping solutions for their high-precision machining operations. The fixtures’ stability and precision helped them achieve the stringent quality standards required in the aerospace industry, resulting in superior performance and reliability of their products.

Future Trends

Advancements in Technology

The future of Clamping Fixture will be shaped by advancements in technology, leading to more efficient and precise solutions.

Automation and Smart Fixtures

The integration of automation and smart technologies into Clamping Fixture is a growing trend. These fixtures can be equipped with sensors and IoT connectivity to monitor and adjust the clamping force in real time, enhancing precision and reducing downtime.

Additive Manufacturing

Additive manufacturing, or 3D printing, is revolutionizing the production of Clamping Fixture. This technology allows for the creation of complex and customized fixtures with greater ease and efficiency. Louis Machine is at the forefront of adopting additive manufacturing techniques to produce innovative clamping solutions.

Advanced Materials

The use of advanced materials, such as high-strength alloys and composites, is improving the performance and durability of Clamping Fixture. These materials offer better resistance to wear and tear, ensuring longer service life and reduced maintenance costs.

Market Expansion

The demand for Clamping Fixture is expected to grow as industries continue to seek ways to improve their manufacturing processes.

Emerging Markets

Emerging markets in Asia, Africa, and Latin America are experiencing rapid industrialization, driving the need for advanced manufacturing solutions. Clamping fixture suppliers like Louis Machine are well-positioned to capitalize on this growth by offering high-quality products tailored to these markets’ needs.

Increasing Customization

As manufacturers strive for higher efficiency and precision, the demand for customized clamping solutions is on the rise. Louis Machine’s ability to provide tailored fixtures that meet specific requirements will be a key factor in their continued success.

Sustainability

Sustainability is becoming a critical consideration in manufacturing. The development of eco-friendly Clamping Fixture that reduce energy consumption and waste will be an important trend in the industry. Louis Machine is committed to sustainability, incorporating environmentally friendly practices into its production processes.

Conclusion

Clamping Fixture play a crucial role in ensuring the precision and efficiency of manufacturing processes across various industries. As the market continues to evolve, companies like Louis Machine are leading the way with innovative solutions that meet the diverse needs of manufacturers. By staying ahead of technological advancements and focusing on customer satisfaction, Louis Machine is set to remain the best clamping fixture service provider in 2024 and.