Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

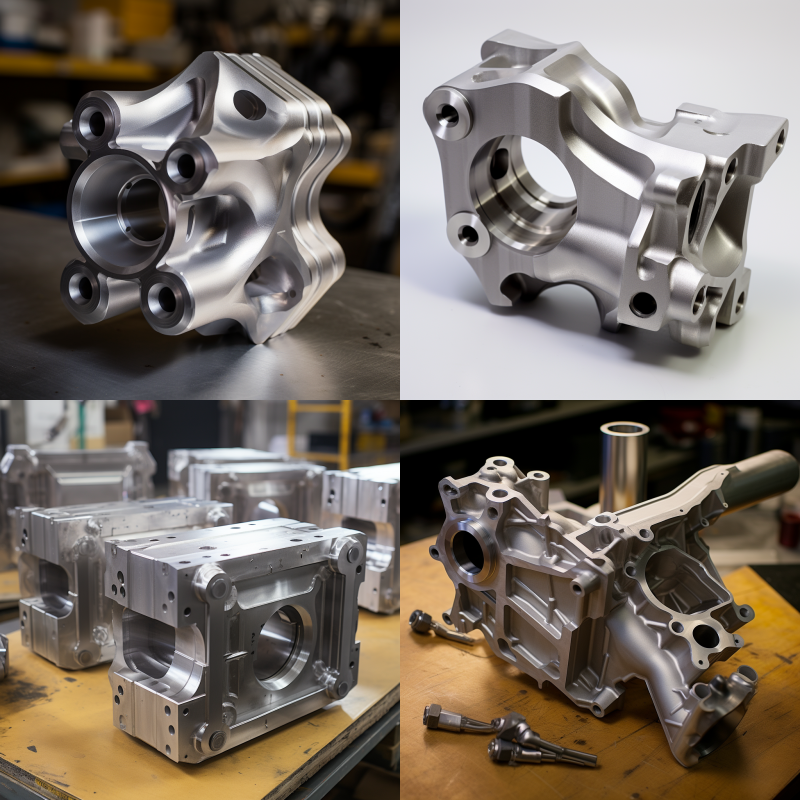

Explore the world of aluminum rapid prototyping

Aluminum rapid prototyping is a cutting-edge manufacturing process designed to quickly and efficiently create physical prototypes of products or components during the product development phase. Rapid prototyping serves as a crucial step in the design iteration process, allowing engineers and designers to assess and test their concepts before proceeding to full-scale production. Aluminum, renowned for its lightweight yet durable properties, has gained prominence as a preferred material for rapid prototyping. Its versatility, excellent machinability, and heat-resistant qualities make it ideal for producing functional prototypes that closely mimic the properties of final products.

Advantages of Aluminum Rapid Prototyping

Swift and Efficient Prototyping

Aluminum rapid prototyping stands out for its exceptional speed and efficiency in the product development cycle. Traditional prototyping methods often entail time-consuming processes, including intricate tooling setups and multiple design iterations. In stark contrast, aluminum rapid prototyping streamlines the entire process, allowing for the rapid creation of prototypes. Engineers and designers benefit from the ability to swiftly validate their designs, make necessary adjustments, and expedite the time-to-market for new products.

Cost-Efficiency Redefined

Cost efficiency plays a pivotal role in product development, and aluminum rapid prototyping offers substantial cost advantages. Conventional methods frequently entail substantial expenses related to tooling and setup, which can be a significant hurdle, particularly for small-scale projects. Aluminum prototyping effectively sidesteps many of these costs, making it a cost-effective option for both small and large-scale production. It significantly reduces material waste and diminishes the need for costly tool changes between different design iterations.

Material Excellence and Versatility

Aluminum’s unique material properties make it an outstanding choice for rapid prototyping. It seamlessly blends lightweight attributes with high strength, corrosion resistance, and exceptional thermal conductivity. This versatility enables the creation of prototypes that closely emulate the material properties of final products. This characteristic makes aluminum rapid prototyping particularly suited for functional testing, as prototypes can accurately replicate the behavior of production materials. Whether deployed for structural components or intricate parts, aluminum showcases the flexibility to meet a broad spectrum of design prerequisites.

Applications of Aluminum Rapid Prototyping

Precision Takes Flight: Aerospace and Automotive Industries

In the aerospace and automotive sectors, where precision, performance, and safety reign supreme, aluminum rapid prototyping plays a pivotal role. Engineers can swiftly craft lightweight yet robust prototypes. These prototypes find application in various components, spanning aircraft parts, automotive elements, and even complete vehicle frames. Rigorous testing of these prototypes guarantees that final products adhere to stringent industry standards concerning structural integrity, aerodynamics, and safety.

Unleashing Innovation: Consumer Electronics and Product Design

In the realm of consumer electronics and product design, aluminum rapid prototyping serves as a catalyst for transforming innovative concepts into reality. Be it smartphones, laptops, household appliances, or wearable gadgets, aluminum prototypes empower designers to evaluate form, function, and ergonomics expeditiously. This iterative process ensures that products not only exhibit captivating aesthetics but also deliver flawless performance in the hands of consumers.

Advancing Healthcare: Medical Device Development

The field of medical device development mandates precision and reliability as non-negotiable prerequisites. Aluminum rapid prototyping seamlessly facilitates the creation of intricate prototypes for medical devices, encompassing surgical instruments, implantable devices, and diagnostic equipment. These prototypes undergo scrupulous testing to affirm their alignment with rigorous medical standards, thereby ensuring the safety and efficacy of medical procedures.

Industrial Evolution: Manufacturing and Beyond

The industrial and manufacturing sectors harness the power of aluminum rapid prototyping to optimize production processes and construct bespoke components. Manufacturers can swiftly evaluate and enhance production tools, jigs, and fixtures. This streamlined approach fosters efficiency within manufacturing processes, diminishing downtime and elevating overall productivity within industrial settings. Furthermore, custom aluminum parts can be promptly prototyped to cater to specific industrial requirements, ultimately enhancing the performance of equipment and machinery.

Methods and Techniques in Aluminum Rapid Prototyping

Precision with CNC Machining

CNC (Computer Numerical Control) machining stands as a cornerstone of aluminum rapid prototyping. It enables the creation of precise aluminum components with utmost accuracy. CNC machines follow digital instructions to carve, mill, and shape aluminum blocks, turning design concepts into tangible prototypes. The process grants engineers unparalleled control over dimensions, geometries, and intricacies.

3D Printing and Additive Manufacturing

3D printing and additive manufacturing have revolutionized prototyping. These cutting-edge techniques construct aluminum prototypes layer by layer, offering remarkable design freedom. Aluminum powder is fused, sintered, or melted in precise patterns to craft intricate structures. 3D printing minimizes material waste, expedites prototyping, and enables the production of complex, lightweight aluminum components.

Precision through Die Casting and Injection Molding

Die casting and injection molding methods enhance aluminum rapid prototyping by facilitating the creation of intricate, high-quality prototypes. Die casting involves injecting molten aluminum into precision molds, yielding detailed prototypes with minimal post-processing requirements. Injection molding employs similar principles, using heated aluminum pellets to form prototypes. These techniques excel in producing aluminum parts with exceptional dimensional accuracy and surface finish.

Laser Cutting and Engraving for Precision

Laser cutting and engraving have found their niche in aluminum rapid prototyping, especially for sheet metal components. High-powered lasers meticulously cut and etch aluminum sheets, delivering precision and speed. Laser technology’s versatility allows for the creation of intricate shapes and patterns in aluminum, making it an ideal choice for specific prototyping needs.

Future Trends and Innovations in Aluminum Rapid Prototyping

Embracing Emerging Technologies and Materials

The future of aluminum rapid prototyping is poised to incorporate groundbreaking technologies and materials. Advancements such as aluminum alloys with enhanced properties, novel 3D printing methods, and innovative surface treatment techniques will further expand the possibilities of aluminum prototyping.

Synergy with Digital Design and Simulation

The integration of aluminum rapid prototyping with digital design and simulation tools will become increasingly prevalent. Engineers will harness advanced software to optimize designs, simulate performance, and streamline the prototyping process. This digital synergy will enhance efficiency, reduce errors, and accelerate the path from concept to prototype.

Embracing Sustainability and Eco-Friendly Practices

The shift towards sustainable and eco-friendly approaches in aluminum rapid prototyping is an exciting trend. This includes eco-conscious material sourcing, recycling initiatives, and energy-efficient production methods. As environmental concerns become more pronounced, the industry will respond with innovative solutions that minimize ecological impact while delivering precision prototypes.

In Conclusion

In the realm of product development and innovation, Aluminum Rapid Prototyping stands as a game-changer. Its speed, cost-effectiveness, and material versatility revolutionize the way ideas become reality. Applications span across vital industries, from aerospace to healthcare, propelling progress. However, it’s not without challenges, such as material constraints and post-processing needs. Looking ahead, the future of Aluminum Rapid Prototyping holds promise, with emerging technologies and sustainability at the forefront. As a catalyst for innovation, it empowers engineers and designers to push boundaries and create and reshape the world of manufacturing.