Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

The Evolution of Auto Part Pallets: Trends and Innovations in the Industry

Captivating Beginnings

Have you ever considered the transformative impact of auto part pallets on the automotive industry? These crucial tools do more than just streamline operations; they significantly enhance efficiency across various sectors. As the demands of automotive production and repair evolve, innovations in storage and logistics evolve alongside them. By exploring the journey and transformation of auto part pallets, valuable insights into their increasing importance in modern workshops and warehouses emerge.

Historical Context

The evolution of auto part pallets from simple wooden structures to sophisticated solutions is remarkable. Originally designed for basic storage, they now cater to the specific needs of the automotive industry with advanced designs. With the introduction of new materials and technologies, manufacturers increasingly prioritize durability and functionality in their products. As competition within the automotive sector intensifies, the demand for innovative storage solutions has surged, driving a rapid evolution in both pallet design and functionality.

Current Trends

The current trend favors modular and customizable pallets that adapt to various storage requirements. Increasingly, manufacturers are incorporating advanced materials like high-density plastics and composites, which offer both strength and lightweight properties. Additionally, smart technology is making its way into the realm of auto part pallets, enhancing tracking and inventory management capabilities. Such advancements not only boost efficiency but also foster a more sustainable and cost-effective approach to auto parts storage.

Cost-Effective Solutions: Why Auto Part Pallets are a Smart Investment

Maximizing Value

The decision to invest in auto part pallets proves to be strategic, yielding significant cost savings over time. These pallets are specifically designed to enhance operational efficiency, minimizing the time and labor associated with inventory management. By streamlining processes, businesses can redirect resources to critical areas, ultimately increasing profitability. The initial investment in high-quality pallets pays off through improved workflows and reduced operational costs.

Durability and Longevity

Durability stands out as a key advantage of modern auto part pallets. Constructed from robust materials, such as Sweden ASSAB mold steel, these pallets withstand heavy loads and frequent use. This resilience translates into a longer lifespan, significantly reducing the need for replacements and minimizing waste. Businesses can depend on these pallets to maintain structural integrity, ensuring they adequately support the weight and complexity of automotive parts without compromise.

Enhancing Operational Efficiency

By optimizing auto parts organization, these pallets enhance operational efficiency. With appropriate storage solutions, workshops can access needed parts quickly, reducing downtime and boosting overall productivity. This efficiency extends beyond the workshop floor; it influences supply chains and customer satisfaction as well. The ability to swiftly locate and retrieve parts leads to faster turnaround times and happier clients, making auto part pallets an essential investment.

Custom Auto Part Pallets: Tailoring Solutions for Unique Needs

Personalized Designs

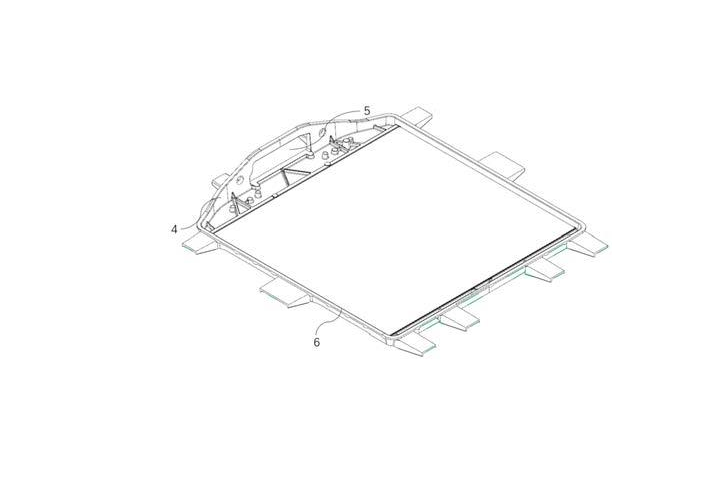

In the diverse world of automotive manufacturing, a one-size-fits-all approach rarely suffices. Custom auto part pallets provide tailored solutions that address the unique requirements of various businesses. By collaborating with suppliers like Louis Machine, companies can design pallets that align with specific dimensions and load capacities. Such customization ensures that each pallet optimally supports the specific auto parts being stored, minimizing the risk of damage and enhancing overall efficiency.

Innovations in Customization

Advancements in manufacturing techniques, such as 3D printing, have made creating bespoke pallets for specific applications easier than ever. This innovative approach allows manufacturers to experiment with designs and materials, resulting in products that are not only functional but also optimized for their intended use. Custom auto part pallets can also feature ergonomic handles and reinforced edges, increasing their user-friendliness and effectiveness.

Addressing Unique Challenges

Each workshop and warehouse presents its own challenges, whether related to space constraints, weight distribution, or specific part sizes. Custom pallets are designed to tackle these challenges head-on. For instance, a workshop specializing in heavy-duty parts may require reinforced pallets, while one that handles smaller components might benefit from more compact designs. By providing solutions tailored to these unique situations, businesses can significantly improve operational efficiency and safety.

From Warehouse to Workshop: The Journey of Auto Part Pallets

The Logistics Chain

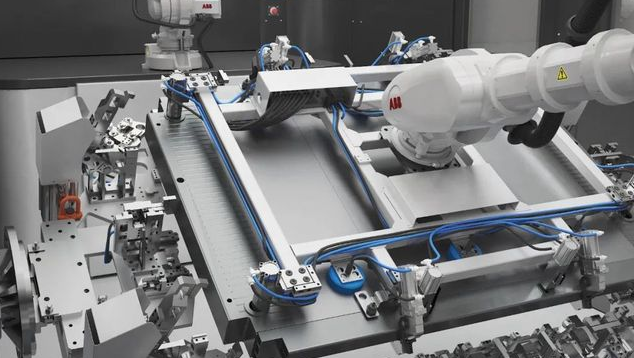

The journey of an auto part pallet commences in the manufacturing facility, where high-quality materials and advanced technology come together to produce them. Once manufactured, these pallets transition to warehouses, where they play a pivotal role in inventory management. Their ability to efficiently stack and organize parts makes them invaluable in large-scale operations. Suppliers like Louis Machine are essential in ensuring these pallets are readily available for businesses in need.

Transition to Workshop Use

As the pallets reach the workshop, their true potential unfolds. They enable mechanics and technicians to organize tools and parts effectively, facilitating quick access and reducing search times. This transition from warehouse to workshop underscores the vital role of these pallets in maintaining a smooth operational flow. A well-organized workshop translates into faster service times and improved customer satisfaction.

Continuous Improvement

The journey of auto part pallets does not conclude once they arrive in the workshop. Ongoing feedback from users fuels continuous improvements and innovations in pallet design and functionality. As the industry evolves, so do the requirements for storage solutions, prompting manufacturers to adapt and enhance their offerings. This continuous process ensures that auto part pallets remain relevant and effective, supporting the dynamic needs of the automotive sector.

Conclusion

In conclusion, auto part pallets from Louis Machine have experienced remarkable evolution, transforming into indispensable tools within the automotive industry. Their development has been driven by the need for greater efficiency, organization, and adaptability in an increasingly competitive market. Offering cost-effectiveness and customizability, these pallets enable businesses to optimize their operations and manage inventory effectively. They play an integral role in the logistics chain, facilitating smoother workflows and quicker access to essential parts, ultimately improving service delivery.

As businesses seek to enhance operational efficiency, investing in modern auto part pallets emerges as a wise choice. By comprehending the journey of these pallets and the innovative technologies shaping their future, companies can strategically leverage their benefits to address unique challenges. This proactive approach not only fosters growth but also positions businesses to thrive in an ever-evolving industry landscape, ensuring long-term success and a competitive edge.