Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Importance of Car Part Com in the Automotive Industry

Car parts form the backbone of the automotive industry, playing a crucial role in vehicle functionality, safety, and performance. From engine components to intricate electronic systems, every part contributes to the overall reliability and efficiency of automobiles. As vehicles evolve to meet environmental and technological challenges, the demand for advanced, high-quality car parts continues to grow.

Introduction to Louis Machine: Provider of Machining Solutions

Car Part Com: Louis Machine stands at the forefront of precision machining solutions tailored for the automotive sector. With a reputation for excellence in manufacturing and engineering, Louis Machine specializes in producing customized car parts that adhere to the highest industry standards. Their expertise spans a wide range of materials and technologies, ensuring they meet the diverse needs of automotive manufacturers worldwide.

Latest Trends in Car Parts

Shift Towards Advanced Materials

In response to stringent emissions regulations and consumer demand for fuel-efficient vehicles, there has been a notable shift towards lightweight materials in car part manufacturing. Louis Machine leverages advanced materials such as carbon fiber composites and aluminum alloys to reduce weight without compromising strength, thereby enhancing fuel efficiency and overall vehicle performance.

Impact of Electrification on Car Part Design

The rise of electric vehicles (EVs) has revolutionized car part design, necessitating components like battery housings, electric motors, and power electronics that are lightweight, compact, and efficient. Louis Machine integrates state-of-the-art machining techniques to manufacture precise EV components that contribute to the durability and performance of electric vehicles.

Digitalization and IoT Integration

Digitalization has transformed car parts into intelligent components capable of real-time monitoring and diagnostics. Louis Machine incorporates IoT (Internet of Things) technologies and sensors into their car parts to enable data-driven insights for predictive maintenance, optimizing vehicle reliability and reducing downtime for automotive manufacturers.

Meeting Machining Project Needs

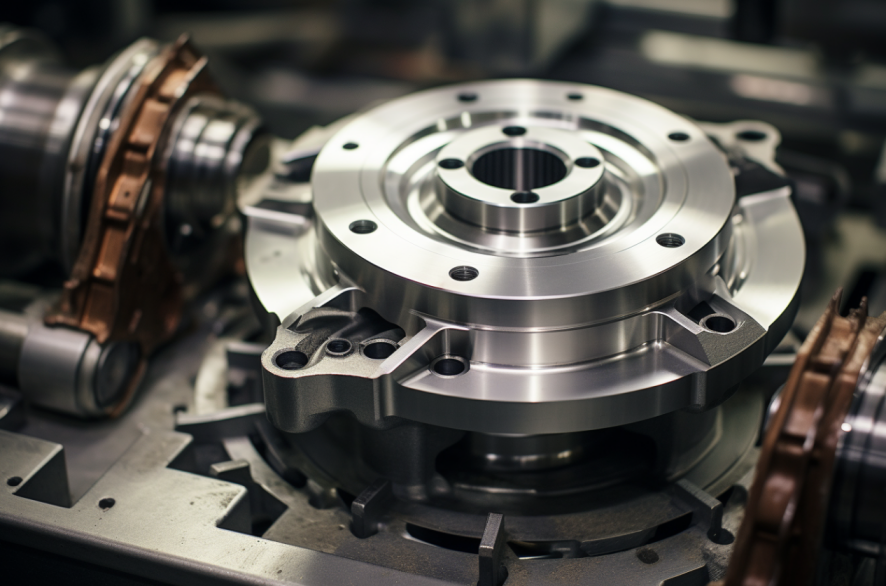

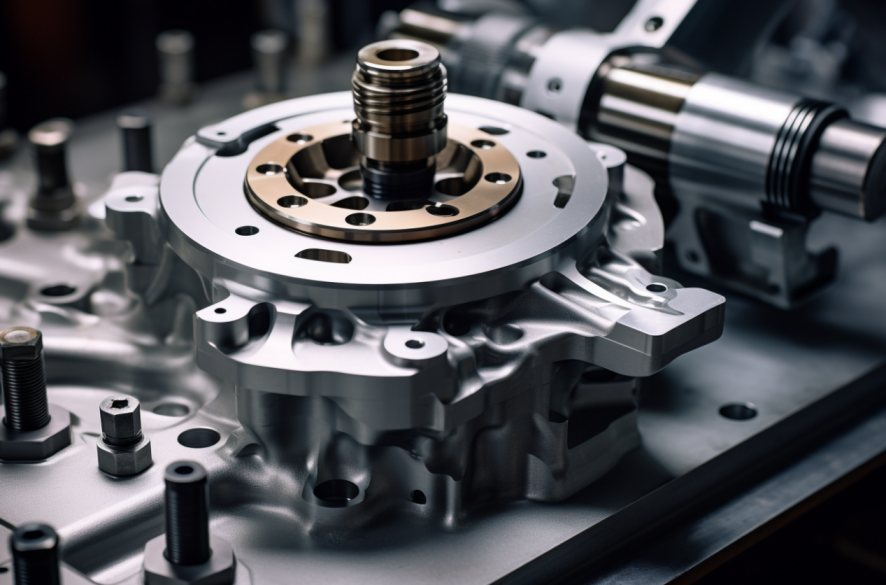

Precision Machining Expertise

Louis Machine excels in precision machining, a critical requirement in automotive manufacturing where components must meet exacting specifications for fit, form, and function. Their advanced CNC machining capabilities ensure that each car part is crafted with utmost precision, guaranteeing reliability and longevity under demanding operational conditions.

Facilitating Custom Prototyping

Innovation in car part development often begins with rapid prototyping to test and refine designs swiftly. Car Part Com: Louis Machine supports iterative design processes by offering rapid prototyping services that enable automotive engineers to validate concepts and make informed decisions early in the development cycle. This iterative approach accelerates time-to-market for new vehicle models and enhances product innovation.

Addressing Industrial Needs and Challenges

Louis Machine prioritizes meeting industrial needs through adherence to quality standards and optimizing supply chain efficiency.

Compliance with Quality Standards

Louis Machine places a strong emphasis on quality management, ensuring compliance with industry-specific standards such as ISO 9001:2015. This certification underscores their commitment to producing car parts that meet stringent criteria for reliability, durability, and safety. By adhering to these standards, Louis Machine assures customers of consistent quality throughout the manufacturing process, from initial design to final production.

Louis Machine’s quality control system is integral to their operations, enabling traceability and accountability at every stage of production. This systematic approach not only enhances product reliability but also instills confidence in automotive manufacturers relying on Louis Machine for critical components.

Strategies for Supply Chain Efficiency

Efficient supply chain management is essential in modern manufacturing to minimize lead times and optimize production schedules. Car Part Com: Louis Machine employs strategic measures to streamline their manufacturing processes and ensure timely delivery of customized car parts. By integrating advanced logistics and production planning techniques, they effectively manage resources and respond swiftly to fluctuating market demands.

Louis Machine’s commitment to supply chain efficiency extends beyond operational logistics to encompass strong relationships with suppliers and partners. This collaborative approach enables them to maintain a reliable flow of materials and components, thereby reducing disruptions and enhancing overall production efficiency.

Customizing Car Parts from Louis Machine

Car Part Com: Louis Machine excels in providing tailored solutions and flexible design capabilities to meet diverse customer requirements.

Tailored Solutions Based on Client Specifications

One of Louis Machine’s core strengths lies in their ability to customize car parts according to precise client specifications. Whether it’s modifying existing designs or developing entirely new components, they collaborate closely with automotive manufacturers to understand unique project needs. This collaborative approach ensures that each car part aligns perfectly with functional and aesthetic requirements, contributing to enhanced vehicle performance and customer satisfaction.

Louis Machine’s comprehensive understanding of automotive engineering allows them to offer innovative solutions that optimize component functionality and manufacturability. From initial concept to final production, they leverage their expertise to deliver tailored solutions that meet or exceed customer expectations.

Design Flexibility and Modification Capabilities

Flexibility in design is crucial in the automotive industry, where evolving technologies and market trends often necessitate rapid adjustments to car part designs. Louis Machine excels in accommodating unique design requirements and modifications, leveraging advanced CAD/CAM software and precision machining capabilities. This flexibility enables them to iterate designs efficiently, incorporate design changes seamlessly, and respond promptly to design optimizations or regulatory updates.

Louis Machine’s agile approach to design flexibility ensures that automotive manufacturers can adapt quickly to market dynamics without compromising on product quality or performance. By offering scalable manufacturing solutions and rapid prototyping services, they empower customers to innovate and stay ahead in a competitive industry landscape.

Why Choose Car Part Com: Louis Machine?

Louis Machine distinguishes itself as a premier provider of machining solutions for automotive parts, offering unparalleled expertise and service excellence.

Louis Machine boasts a rich history and robust infrastructure, starting with its establishment in 2011 through the merger of precision mold and hardware product factories. Over the years, they have expanded their capabilities to include plastic injection molding, metal hardware parts processing, and specialized automotive parts manufacturing.

Their commitment to quality is evident in their ISO certifications and rigorous quality control systems, ensuring that every car part meets the highest standards of performance and reliability. This dedication to quality assurance extends across their entire operation, from initial design consultations to final product inspections.

Louis Machine’s state-of-the-art manufacturing facilities span over 30,500 square meters and feature more than 130 sets of major equipment, including advanced CNC machines from Germany, Switzerland, and Japan. This extensive infrastructure enables them to achieve exceptional precision and consistency in manufacturing car parts, meeting even the most demanding technical specifications.

Conclusion

Car Part Com: Louis Machine stands as a trusted partner in the automotive industry, providing cutting-edge machining solutions that address the evolving needs of car part manufacturing. By embracing advanced materials, electrification trends, and digitalization, Louis Machine not only meets but exceeds the expectations of automotive manufacturers seeking high-performance, customized components. As the automotive landscape continues to evolve, Louis Machine remains committed to innovation, quality, and customer satisfaction, driving the future of car part manufacturing forward.

This comprehensive blog highlights Louis Machine’s commitment to excellence and innovation in the realm of car part manufacturing, showcasing their capabilities in precision machining and rapid prototyping