Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

2024 CNC Accuracy Service for Automobile Accessory Parts: Louis Machine

Louis Machine specializes in providing high-precision CNC machining services for automobile accessory parts. With a commitment to quality and advanced technology, they ensure that every component meets stringent standards for performance and reliability.

Understanding CNC Accuracy Service

1.1 Definition and Importance

CNC accuracy service refers to the capability of CNC machines to consistently produce parts with high precision and tight tolerances. This is achieved through advanced machining techniques controlled by computer programs, ensuring exact specifications are met for each component. In the automotive industry, where reliability and performance are non-negotiable, CNC accuracy service ensures that parts function seamlessly within complex systems.

1.2 Technologies Involved

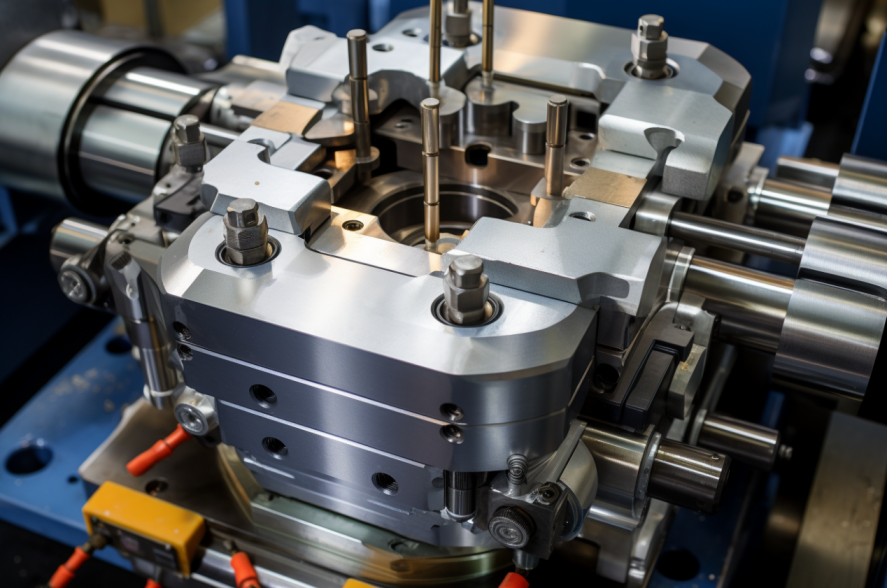

Louis Machine utilizes state-of-the-art CNC machining equipment, including multi-axis machining centers and automated tool changers. These technologies enable precise cutting, drilling, and shaping of raw materials such as metals and plastics, turning them into intricate automobile components with minimal human intervention.

1.3 Benefits for Automobile Parts

The benefits of CNC accuracy service for automobile parts are manifold. It includes enhanced accuracy, repeatability, and efficiency in production processes. Components manufactured with CNC precision are crucial for maintaining vehicle safety standards, reducing assembly time, and minimizing waste in material usage.

Advanced Die-Casting Mold Materials

2.1 Superior Materials: Sweden ASSAB Mold Steel

Louis Machine uses Sweden ASSAB mold steel, known for its exceptional quality and durability. This choice of material ensures that the die-casting molds can withstand high pressure and temperature conditions without compromising on precision.

2.2 Material Testing Laboratory

Louis Machine has established its own material testing laboratory, equipped with state-of-the-art facilities. The laboratory holds accreditation from the China National Accreditation for Conformity Assessment (CNAS), highlighting its capability to conduct comprehensive tests on mold steel and graphite electrodes.

2.3 Traceability and Quality Assurance

Each set of molds manufactured by Louis Machine retains a material sample and a detailed test report for up to two years. This traceability ensures that the quality of their products is consistently monitored and maintained at the highest level.

Advanced Machining Equipment

3.1 Japan’s MAKINO Five-Axis Machining Center

Louis Machine utilizes Japan’s renowned MAKINO five-axis machining center. This advanced equipment allows for intricate and precise machining operations, crucial for manufacturing complex automobile parts with tight tolerances.

3.2 Gantry Machining Center

In addition to the MAKINO center, Louis Machine employs a gantry machining center. This versatile equipment further enhances their capability to handle large and heavy parts with precision and efficiency.

3.3 Die Casting Machines

Louis Machine operates high-capacity die casting machines ranging from 3000T to 6000T. These machines are essential for producing robust automobile accessory parts that meet the rigorous demands of the automotive industry.

Commitment to Product Quality

4.1 Quality Control Process

Louis Machine implements a rigorous quality control process throughout the manufacturing cycle. From material selection and testing to machining and final inspection, every step adheres to strict quality standards.

4.2 Continuous Improvement

The company is dedicated to continuous improvement in its manufacturing processes. They regularly invest in the latest technology and training for their staff to ensure that they remain at the forefront of precision machining.

4.3 Customer Satisfaction

Louis Machine prioritizes customer satisfaction by delivering products that not only meet but exceed expectations. Their attention to detail and commitment to quality make them a trusted partner in the automotive accessory parts industry.

Customizing CNC Accuracy Service for Automobile Accessory Parts

5.1 Initial Consultation and Design Phase

Louis Machine begins each project by collaborating closely with the client during the initial consultation phase. This involves understanding the specific requirements of the automobile accessory parts and the desired performance criteria. Engineers and designers work together to optimize designs for manufacturability and cost-effectiveness.

5.2 Material Selection and Testing

Choosing the right materials is fundamental to achieving high precision in CNC machining. Louis Machine offers expertise in selecting materials such as alloy steels, aluminum alloys, and engineering plastics based on the application’s mechanical and thermal requirements. They conduct thorough material testing to ensure compatibility with CNC processes and durability under operational conditions.

5.3 Prototyping and Validation

Before full-scale production, Louis Machine provides prototyping services to validate the design and functionality of automobile accessory parts. Prototypes undergo rigorous testing and inspection to identify any potential issues early in the process. This iterative approach allows for adjustments to be made swiftly, ensuring that the final products meet all performance specifications.

Steps in Customizing CNC Accuracy Service

6.1 Project Planning and Scheduling

Once the design and materials are finalized, Louis Machine creates a detailed project plan and schedule. This outlines milestones, deadlines, and resource allocation to streamline the manufacturing process and meet client expectations effectively.

6.2 Precision Machining Processes

Louis Machine’s CNC accuracy service encompasses a range of precision machining processes. This includes milling, turning, drilling, and grinding operations performed with high-speed CNC machines. Each step is meticulously controlled to achieve dimensional accuracy, surface finish, and geometric tolerances as per design specifications.

6.3 Quality Assurance and Inspection

Throughout production, Louis Machine implements stringent quality assurance protocols. They utilize advanced metrology equipment for dimensional inspection, surface analysis, and material testing. This ensures that every automobile accessory part meets regulatory standards and customer requirements before leaving the facility.

Why Choose Louis Machine for CNC Accuracy Service?

7.1 Expertise and Experience

With years of experience in CNC machining for the automotive industry, Louis Machine has honed its expertise in delivering precision components. Their team of skilled engineers and technicians is adept at handling complex projects and optimizing manufacturing processes for efficiency and quality.

7.2 Commitment to Innovation

Louis Machine continuously invests in cutting-edge technologies and training programs to stay ahead in CNC accuracy service. This commitment to innovation enables them to tackle new challenges in automobile accessory part manufacturing and adapt to evolving industry demands.

7.3 Customer-Centric Approach

At Louis Machine, customer satisfaction is paramount. They prioritize open communication, responsiveness, and transparency throughout the project lifecycle. Clients benefit from personalized solutions, timely deliveries, and ongoing support to ensure their CNC machining needs are met with excellence.

Conclusion

Louis Machine stands out in the field of CNC accuracy service for automobile accessory parts due to its use of superior materials, advanced machining equipment, and stringent quality control measures. By leveraging Sweden ASSAB mold steel, a sophisticated testing laboratory, and cutting-edge machining centers, they consistently deliver high-precision components for their clients. Whether it’s through their commitment to quality assurance or their dedication to continuous improvement, Louis Machine remains a reliable choice for manufacturers seeking top-tier CNC machining services.