Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Why Effective Hourly Rate (EHR) Matters: Insights Now

Optimizing the Effective Hourly Rate (EHR) is pivotal for machining companies aiming to enhance cost efficiency and competitive edge in the global market. Louis Machine stands out as a reliable partner, offering not only advanced machining capabilities and extensive industry experience but also a steadfast commitment to quality and customer satisfaction. By choosing Louis Machine, businesses can leverage cutting-edge technology, skilled workforce, and streamlined processes to achieve lower EHR and superior production outcomes, thereby ensuring sustained success and profitability in the manufacturing sector.

What is EHR: Effective Hourly Rate in Machining Services

In the realm of machining services, the term “EHR” often abbreviates “Effective Hourly Rate.” This metric encapsulates the comprehensive cost incurred per operational hour by machine shops or machining service providers. It encompasses various critical factors, including direct labor expenses, overhead costs, depreciation of machinery, tooling expenses, and other operational outlays relevant to the machining processes undertaken. Calculating the Effective Hourly Rate is pivotal for these businesses as it provides a clear understanding of their true operational expenses, thereby influencing their pricing strategies and overall profitability.

Effective Hourly Rate serves as a crucial benchmark for machining service providers, allowing them to gauge their cost-effectiveness and competitiveness within the market. By accurately assessing these expenses, businesses can make informed decisions regarding pricing structures, budget allocations for equipment upgrades or maintenance, and strategic planning aimed at optimizing operational efficiency.

Latest Market Trends in EHR: Effective Hourly Rate

The machining industry, driven by technological advancements and increasing automation, has witnessed notable trends concerning Effective Hourly Rate calculations. One prominent trend involves the integration of advanced software systems that streamline cost calculations and optimize resource allocation. Modern machining facilities are increasingly adopting sophisticated ERP (Enterprise Resource Planning) and MES (Manufacturing Execution System) solutions that not only enhance operational efficiency but also provide real-time insights into cost metrics such as EHR.

Moreover, there is a growing emphasis on sustainability and energy efficiency within machining operations, directly impacting the Effective Hourly Rate. Machine shops are exploring ways to minimize energy consumption, reduce material waste, and implement eco-friendly practices that not only lower operational costs but also enhance their market appeal as environmentally responsible suppliers.

Louis Machine: Enhancing Competitiveness Through Effective Hourly Rate

Louis Machine, a leading name in the machining industry, excels in optimizing the Effective Hourly Rate to drive cost savings and enhance market competitiveness for its clients. With a robust portfolio spanning diverse machining services, Louis Machine leverages advanced technologies and stringent operational protocols to deliver superior quality while maintaining cost efficiency.

Machining Services Offered by Louis Machine

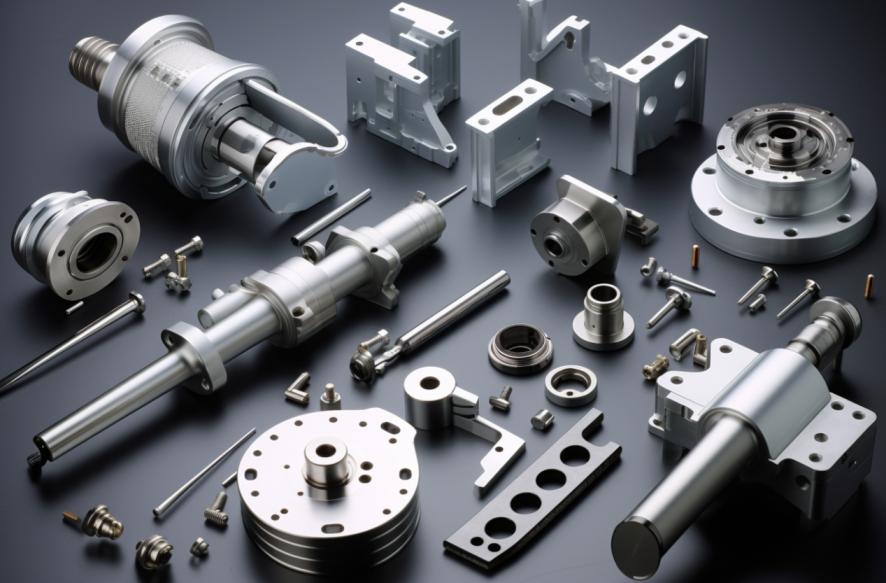

Louis Machine specializes in a wide array of machining services tailored to meet diverse industry needs:

EDM Machining: Louis Machine utilizes state-of-the-art Electrical Discharge Machining (EDM) techniques to achieve intricate designs and precise tolerances in metals, ensuring high-quality output at competitive rates.

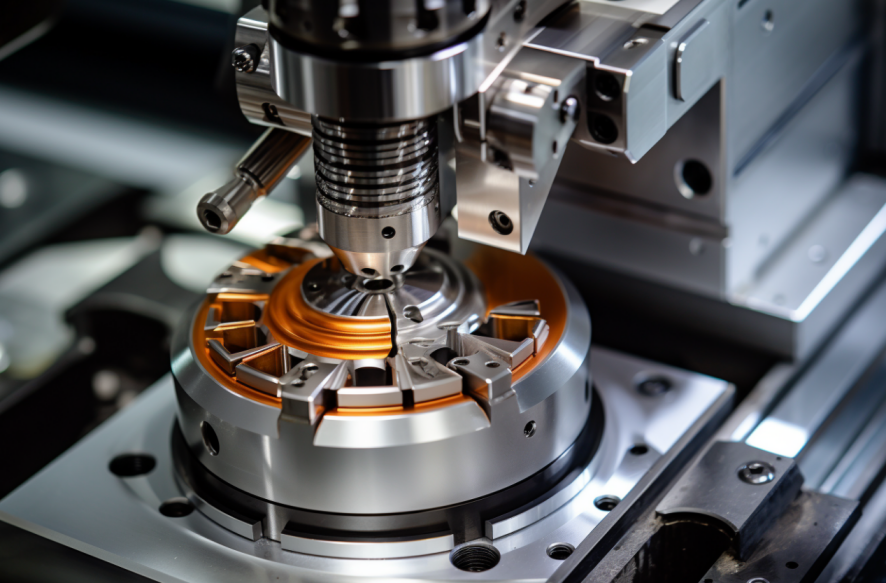

Five-Axis Machining: Leveraging advanced CNC capabilities, Louis Machine offers precise five-axis machining solutions ideal for complex geometries and multi-dimensional components.

Screw Machining: Known for its expertise in high-volume production, Louis Machine delivers efficient screw machining services that optimize production cycles and reduce per-unit costs.

UAV Parts: Catering to the aerospace sector, Louis Machine manufactures lightweight and durable parts essential for unmanned aerial vehicles (UAVs), meeting stringent industry standards.

Smart Ring Production: In the field of wearable technology, Louis Machine excels in producing smart rings with intricate electronic components and precision engineering.

Precision Needle Manufacturing: Serving the medical and pharmaceutical industries, Louis Machine manufactures precision needles with exacting specifications, ensuring reliability and performance.

Turning Mill Operations: With a focus on versatility and efficiency, Louis Machine offers turning mill services that encompass a wide range of materials and applications, from prototyping to large-scale production.

How Louis Machine Saves Production Costs

Louis Machine implements several strategies to optimize the Effective Hourly Rate and reduce production costs for its clients:

Advanced Machinery and Tooling: By investing in cutting-edge CNC machines and high-performance tooling, Louis Machine enhances productivity and minimizes downtime, thereby lowering the overall Effective Hourly Rate.

Lean Manufacturing Principles: Adopting lean manufacturing principles allows Louis Machine to streamline workflows, eliminate waste, and optimize resource utilization, resulting in significant cost savings without compromising on quality.

Efficient Supply Chain Management: Through strategic partnerships and efficient supply chain management practices, Louis Machine secures competitive pricing for raw materials and components, further driving down production costs.

Continuous Improvement Initiatives: Louis Machine fosters a culture of continuous improvement, regularly evaluating processes, implementing feedback-driven optimizations, and investing in employee training to enhance skills and efficiency.

Strategies to Reduce EHR

Optimized Workflow and Production Planning: Efficient workflow management plays a pivotal role in reducing EHR. Louis Machine emphasizes streamlined production processes that minimize idle time and maximize machine utilization. By integrating advanced scheduling software and lean manufacturing principles, they ensure continuous production flow, reducing overall operational costs per hour.

Investment in Advanced Technology: Louis Machine’s commitment to high-end equipment from Germany, Switzerland, and Japan underscores their strategy to enhance precision and efficiency. Modern CNC machine tools and advanced EDM (Electrical Discharge Machining) technologies enable them to achieve tight tolerances and minimize material waste, thereby lowering the Effective Hourly Rate through improved productivity.

Skilled Workforce and Continuous Training: A highly trained technical team is essential in optimizing EHR. Louis Machine employs experienced engineers and technicians who undergo regular training to stay updated with the latest machining techniques and technological advancements. This expertise allows them to tackle complex machining challenges efficiently, reducing the time and cost involved per production hour.

Why Choose Louis Machine for Effective Hourly Rate (EHR)?

The partner of choice for companies looking to optimize their effective hourly rates by combining advanced capabilities, deep experience and a commitment to quality.

Louis Machine: A Leader in Precision Machining and Manufacturing

Louis Machinery was formed in 2011 by the merger of two precision mold and hardware factories. It has quickly developed into a well-known enterprise in the mechanical processing industry. Situated in Shenzhen, China, a hub of technological innovation, the company boasts a sprawling facility spanning 30,500 m² equipped with over 130 state-of-the-art machines.

Comprehensive Service Offerings

Louis Machine offers a comprehensive range of services, including:

Precision Mold Design and Manufacturing: From initial concept to final production, Louis Machine excels in designing and manufacturing precision molds for various industries, ensuring high-quality standards and cost-effective solutions.

Plastic Injection Molding: Specializing in the production of plastic components with advanced injection molding techniques, Louis Machine meets diverse client requirements with efficiency and precision.

Metal Hardware Parts Processing: Leveraging advanced CNC machining and EDM capabilities, Louis Machine manufactures metal parts with exceptional accuracy and consistency.

Automotive Parts Manufacturing: With a dedicated facility for automotive metal products, Louis Machine serves the stringent demands of the automotive sector, adhering to industry standards and regulations.

Commitment to Quality and Innovation

Louis Machine maintains a rigorous quality control system and holds ISO 9001:2015 certification, ensuring that every product meets or exceeds customer expectations. Their commitment to innovation is evident through continuous investment in technology and infrastructure, aimed at enhancing production efficiency and reducing costs associated with the Effective Hourly Rate.

Conclusion

In conclusion, the Effective Hourly Rate (EHR) is a pivotal metric in the machining industry, influencing pricing strategies, operational efficiency, and overall profitability. Louis Machine exemplifies industry leadership by optimizing EHR through advanced technologies, precision manufacturing processes, and a commitment to cost-effective solutions. By leveraging their diverse machining capabilities and strategic cost-saving initiatives, Louis Machine not only meets but exceeds client expectations, positioning itself as a preferred partner for businesses seeking reliable, high-quality machining services. As the industry evolves, monitoring and optimizing EHR will remain essential for sustaining competitiveness and driving growth in machining operations worldwide.