Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Five Axis Machining: Enhancing Surface Finish and Accuracy

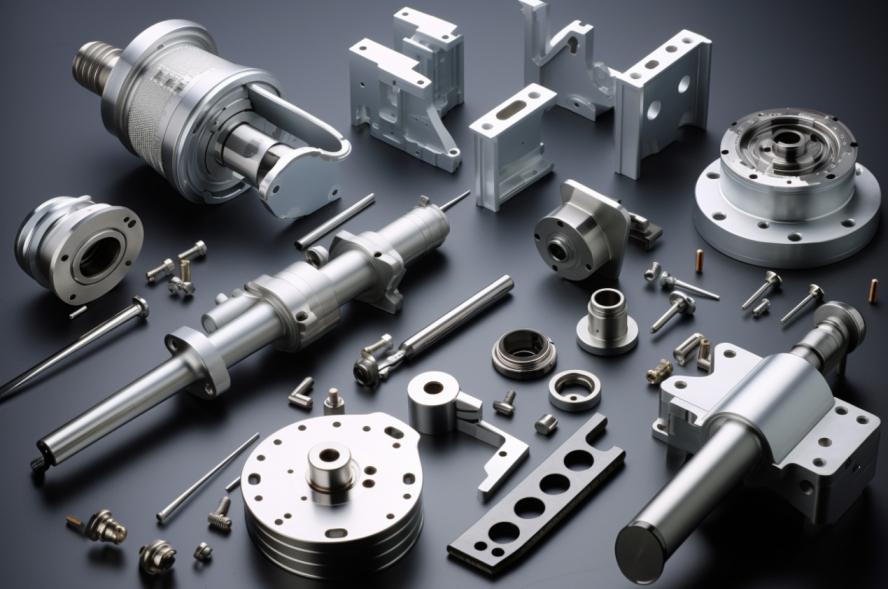

In the realm of advanced manufacturing, Five Axis Machining stands out as a pinnacle of precision and capability. This cutting-edge technology allows for intricate, complex designs to be crafted with unprecedented accuracy and efficiency. From automotive parts to electronic consumer products and precision hardware components, the versatility of Five Axis Machining is unparalleled, making it indispensable in modern industrial applications.

What is Five Axis Machining?

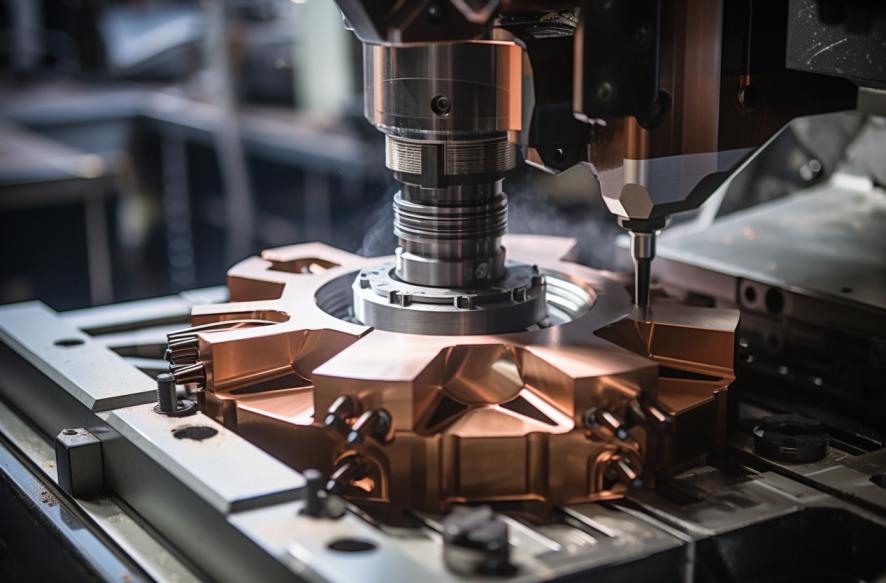

Five Axis Machining refers to the technique of machining parts and components using a computer numerical control (CNC) machine tool with five axes of motion. Unlike traditional machining methods that typically operate on three axes (X, Y, and Z), five axis machines can move along two additional rotary axes, often referred to as A and B axes. This additional freedom of movement enables the machine to approach the workpiece from any angle, facilitating the production of highly complex geometries that would be impractical or impossible to achieve with fewer axes.

Five Axis Machining is prized for its ability to reduce setup times, increase machining accuracy, and enhance surface finish quality. By allowing the cutting tool to access multiple sides of the workpiece without repositioning, it minimizes errors and improves overall productivity. This capability makes it ideal for industries that demand precision, such as aerospace, automotive, medical device manufacturing, and more.

Customizing Your Five Axis Machining Experience

Louis Machine offers customizable Five Axis Machining solutions tailored to meet diverse industrial needs. Whether you require intricate automotive accessory parts, high-precision electronic consumer products, or complex precision hardware components, Louis Machine leverages its expertise and advanced technology to deliver exceptional results. Customization options include selecting the appropriate machine specifications, tooling configurations, and material considerations to optimize the manufacturing process for specific project requirements.

When customizing your Five Axis Machining solution, considerations such as material compatibility, part complexity, dimensional accuracy, and surface finish requirements are paramount. Louis Machine collaborates closely with clients to understand these specifications, ensuring that each component produced meets exacting standards and performance criteria. This collaborative approach not only enhances product quality but also accelerates time-to-market and reduces production costs.

Louis Machine’s commitment to customization extends beyond technical specifications. They provide comprehensive support throughout the manufacturing process, from initial design consultation to post-production quality assurance. Their experienced engineers and technicians work closely with clients to refine designs, optimize machining strategies, and implement rigorous quality control measures, ensuring consistency and reliability in every batch of machined components.

Addressing Various Project Needs

Automobile Accessory Parts: The automotive industry relies on Five Axis Machining to manufacture critical components with precision and efficiency. Louis Machine’s expertise in machining engine parts, transmission components, and chassis elements ensures that automotive manufacturers can meet stringent performance and safety standards. Whether producing prototypes or scaling production volumes, Five Axis Machining enables the creation of lightweight, durable parts that enhance vehicle performance and reliability.

Electronic Consumer Products: In the fast-paced world of electronic consumer products, precision and design flexibility are essential. Louis Machine excels in machining intricate housings, connectors, and internal components for smartphones, tablets, wearables, and other electronic devices. By leveraging Five Axis Machining, they can achieve tight tolerances and intricate geometries that enhance product aesthetics, functionality, and durability, meeting the demands of today’s tech-savvy consumers.

Precision Hardware Parts: From specialized tooling components to aerospace-grade fittings, precision hardware parts require meticulous attention to detail and uncompromising quality. Louis Machine’s advanced Five Axis Machining capabilities enable the production of complex, high-strength components that withstand harsh environments and rigorous performance requirements. Their expertise in material selection and machining techniques ensures that each part meets exact specifications, contributing to the reliability and longevity of critical industrial equipment.

How Five Axis Machining Solves These Challenges

Five Axis Machining offers several advantages that directly address the challenges faced by industries such as automotive, electronics, and precision manufacturing:

Complex Geometries: By allowing simultaneous machining from multiple angles, Five Axis Machining enables the production of intricate shapes and contours that are difficult to achieve with traditional methods. This capability is essential for creating aerodynamic automotive components, compact electronic enclosures, and intricate hardware parts with optimal strength-to-weight ratios.

Reduced Setup Times: The ability to access multiple sides of a workpiece without repositioning significantly reduces setup times and increases machining efficiency. This is particularly beneficial for high-mix, low-volume production runs common in industries like electronics, where rapid prototyping and design iterations are frequent.

Improved Surface Finish and Accuracy: Five Axis Machining enhances surface finish quality by minimizing tool marks and vibrations that can affect the final product’s appearance and functionality. Tighter tolerances and smoother finishes are critical in applications where components must fit precisely or interact seamlessly with other parts.

Enhanced Productivity: By streamlining the manufacturing process and reducing the need for manual intervention, Five Axis Machining improves overall productivity and throughput. This efficiency gain translates into faster lead times, reduced production costs, and increased profitability for manufacturers across various industries.

Louis Machine’s dedication to innovation and precision ensures that their Five Axis Machining services not only meet but exceed the expectations of clients in automotive, electronics, and precision hardware sectors. Their commitment to quality, reliability, and customer satisfaction positions them as a trusted partner in the ever-evolving landscape of advanced manufacturing.

About Louis Machine

A History of Excellence Louis Machine, formally established in March 2011, emerged from the merger of two single precision mold and hardware product factories. Located in Shenzhen, China, a hub of industrial innovation, the company has rapidly grown into a specialized manufacturer of automotive parts, plastic products injection, precision parts, and mold production. With a facility spanning 30,500 square meters and housing over 130 large-scale equipment, Louis Machine has solidified its position as a leader in the industry.

Comprehensive Capabilities Louis Machine is a professional machining company with extensive capabilities in precision mold design and manufacturing, plastic injection molding production, metal hardware parts processing, and automotive parts manufacturing. The company offers a one-stop solution that includes design, manufacturing, injection molding or die casting, and mass parts processing. This comprehensive approach ensures streamlined operations, reduced lead times, and consistent quality across all stages of production.

Experienced Team The success of Louis Machine is driven by its experienced technical members and management personnel. The team comprises senior engineers and skilled technicians who bring decades of experience to the table. Their expertise in high-precision equipment, advanced technology, and modern management concepts ensures that Louis Machine remains at the forefront of the machining industry. Continuous learning and development are core to the company’s ethos, allowing them to deliver cutting-edge solutions to their clients.

Our Experience

Advanced Technology Integration Louis Machine continuously integrates high-precision equipment and advanced technology into its operations. This commitment to technological advancement ensures that the company can meet the stringent demands of modern manufacturing. By hiring senior engineers and adopting the latest management concepts, Louis Machine has built a robust foundation of knowledge and capability. This foundation allows them to produce precision plastic products that meet and exceed customer expectations.

Years of Accumulated Expertise With years of experience and accumulation, Louis Machine has honed its skills in providing high-quality precision plastic products. This expertise is not just limited to plastic; the company excels in metal hardware parts processing and automotive parts manufacturing as well. Their vast experience across various sectors enables them to offer versatile solutions tailored to the unique requirements of each industry.

Commitment to Quality Quality is at the heart of Louis Machine’s operations. The company has established a strict quality control system that ensures the traceability and durability of its products. This rigorous approach to quality has earned Louis Machine the trust of customers both domestically and internationally. Their adherence to integrity and business values further strengthens their reputation as a reliable partner in precision manufacturing.

Conclusion

In conclusion, Five Axis Machining represents a transformative technology in the realm of precision manufacturing. Its ability to handle complex geometries, reduce setup times, and enhance machining accuracy makes it indispensable for industries requiring high-performance components. Louis Machine, with its specialized expertise and commitment to customization, stands at the forefront of delivering tailored Five Axis Machining solutions to meet the diverse needs of automotive, electronics, and precision hardware sectors. By harnessing this advanced technology, manufacturers can achieve new heights of innovation, quality, and efficiency in their production processes, paving the way for future advancements in industrial manufacturing