Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Are Manual Machines Still Relevant in Today’s CNC Industry?

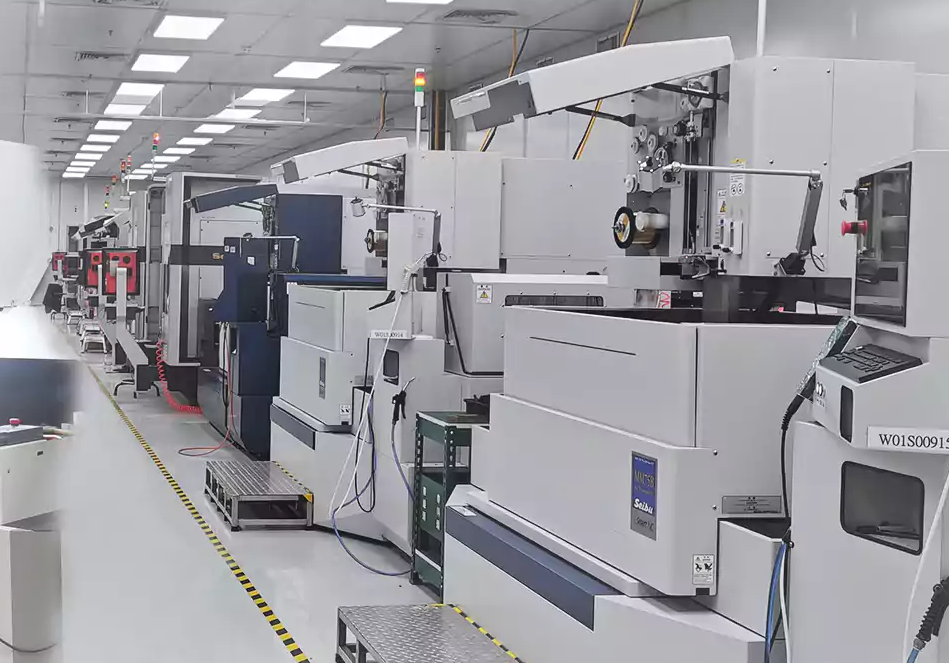

Louis Machine specializes in providing custom CNC solutions tailored to the needs of precision mold design and manufacturing, plastic injection molding production, and metal hardware parts processing. Their expertise lies in delivering high precision machining, handling complex geometries, and ensuring material versatility across various industries such as consumer electronics, medical devices, automotive parts and machinery.

Precision Mold Design and Manufacturing

1.1 High Precision Machining for Mold Cavities

Louis Machine’s custom CNC solutions excel in achieving micron-level accuracy, crucial for creating mold cavities that meet stringent tolerances. This capability is essential in industries where precision molds are required to produce intricate parts with high durability and reliability. By leveraging advanced CNC technology, Louis Machine ensures that even the most complex mold designs are executed flawlessly.

1.2 Handling Complex Geometries

In addition to precision, Louis Machine’s CNC machines are adept at handling complex geometries. This capability allows them to manufacture molds that feature intricate designs and contours. Whether it’s the detailed housing of a consumer electronic device or the ergonomic shape of a medical device component, their CNC solutions enable the production of molds that meet exacting design specifications.

1.3 Versatility in Material Machining

Louis Machine understands the diverse requirements of mold materials, ranging from metals to engineering plastics. Their CNC capabilities extend to working with various materials, ensuring flexibility in mold design and production. This versatility is particularly valuable in industries where different material properties are needed to achieve optimal performance and durability in molded products.

Plastic Injection Molding Production

2.1 From Prototype to Production

Louis Machine supports the entire lifecycle of plastic injection molding, from prototype development to full-scale production. Their CNC machines are equipped to handle both small-batch prototypes and large-volume manufacturing runs with equal precision and efficiency. This capability accelerates time-to-market for new products and allows for seamless scalability as production demands increase.

2.2 Streamlined Mold Production Processes

Efficiency is a hallmark of Louis Machine’s approach to plastic injection molding. They streamline mold production processes to meet tight deadlines without compromising on quality. By optimizing tooling and machining workflows, they reduce lead times and ensure that customers receive molds that are ready for immediate use in injection molding machines.

2.3 Enhancing Mold Durability and Maintenance

Louis Machine places a strong emphasis on tooling optimization to enhance mold durability and minimize maintenance downtime. Their CNC solutions are designed to produce molds that withstand the rigors of high-volume production, thus reducing the need for frequent repairs and replacements. This reliability is crucial for maintaining consistent product quality over extended operational periods.

Metal Hardware Parts Processing Production

3.1 Simultaneous 5-Axis Machining

For industries such as aerospace and machinery, Louis Machine offers CNC capabilities that include simultaneous 5-axis machining. This advanced technology allows for the production of complex metal parts with unparalleled precision and efficiency. The ability to maneuver around multiple axes enables intricate geometries that traditional machining methods cannot easily achieve.

3.2 Precision in Metal Cutting and Shaping

Louis Machine ensures efficiency and accuracy in metal cutting and shaping processes. Their CNC machines are equipped with state-of-the-art tools and controls that enable precise material removal and forming. This precision is critical for meeting the exacting standards of industries where metal parts must perform under demanding conditions and stringent performance criteria.

3.3 Customized CNC Solutions for Metal Alloys

Recognizing the diversity of metal alloys used in aerospace, machinery, and other sectors, Louis Machine offers customized CNC solutions tailored to specific material requirements. Whether it’s aluminum alloys for aerospace components or stainless steel for industrial machinery parts, their machining capabilities are adapted to deliver optimal results for each application.

Automotive Parts Manufacturing

4.1 Scalable Solutions for High-Volume Production

In the automotive industry, the demand for high-volume production of precision parts is constant. Louis Machine offers scalable CNC solutions that can efficiently produce large quantities of components such as engine parts, chassis components, and more. Their manual machines are equipped to handle the rigorous demands of automotive manufacturing, ensuring consistent quality and adherence to tight tolerances.

4.2 Meeting Industry Standards for Performance and Durability

Automotive parts must meet stringent industry standards for performance, durability, and safety. Louis Machine’s CNC solutions are designed to deliver components that not only meet but exceed these standards. By utilizing advanced machining techniques and quality assurance protocols, they ensure that every part manufactured meets the high expectations of automotive manufacturers and end-users alike.

4.3 Developing Custom CNC Tools for Efficient Production Lines

Innovation is at the core of Louis Machine’s approach to automotive parts manufacturing. They specialize in developing custom CNC tools that optimize production processes. These tools are tailored to enhance efficiency, reduce cycle times, and minimize waste, thereby improving overall manufacturing productivity. By continuously innovating and refining their tooling solutions, Louis Machine helps automotive manufacturers stay competitive in a rapidly evolving market.

Custom Solutions by Louis Machine

Louis Machine distinguishes itself by offering bespoke CNC solutions that are meticulously tailored to the specific requirements of each industry they serve.

5.1 Consultative Approach to Understanding Client Requirements

At Louis Machine, every project begins with a thorough consultation process. Their team of experts takes the time to understand the unique challenges and goals of each client. By conducting in-depth discussions and analyses, they gain insights that inform the design and implementation of customized CNC solutions. This consultative approach ensures that the final solution aligns perfectly with the client’s operational needs and strategic objectives.

5.2 Incorporating Advanced CNC Capabilities for Enhanced Productivity

Louis Machine leverages cutting-edge CNC technologies to enhance productivity across all facets of manufacturing. Their manual machines integrate advanced features such as multi-axis machining, robotic automation, and real-time monitoring systems. These capabilities not only streamline production processes but also improve accuracy, consistency, and overall output quality. By staying at the forefront of technological advancements, Louis Machine empowers their clients to achieve greater efficiency and competitiveness in their respective markets.

5.3 Support and Maintenance to Ensure Peak Performance

Beyond delivering state-of-the-art CNC solutions, Louis Machine is committed to providing comprehensive support and maintenance services. They offer tailored service packages that include regular inspections, preventive maintenance, troubleshooting, and technical support. This proactive approach helps clients minimize downtime, optimize machine performance, and extend the lifespan of their equipment. Whether it’s on-site assistance or remote diagnostics, Louis Machine’s dedicated support team ensures that their clients’ operations run smoothly without interruptions.

Conclusion

Louis Machine stands out as a leading provider of custom CNC solutions, catering to the specialized needs of precision mold design and manufacturing, plastic injection molding production, and metal hardware parts processing. Their commitment to high precision, efficiency, and material versatility ensures that customers in diverse industries receive molds and parts that meet the highest standards of quality and performance. By leveraging advanced CNC technology and a customer-centric approach, Louis Machine continues to drive innovation and excellence in manufacturing processes worldwide.