Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

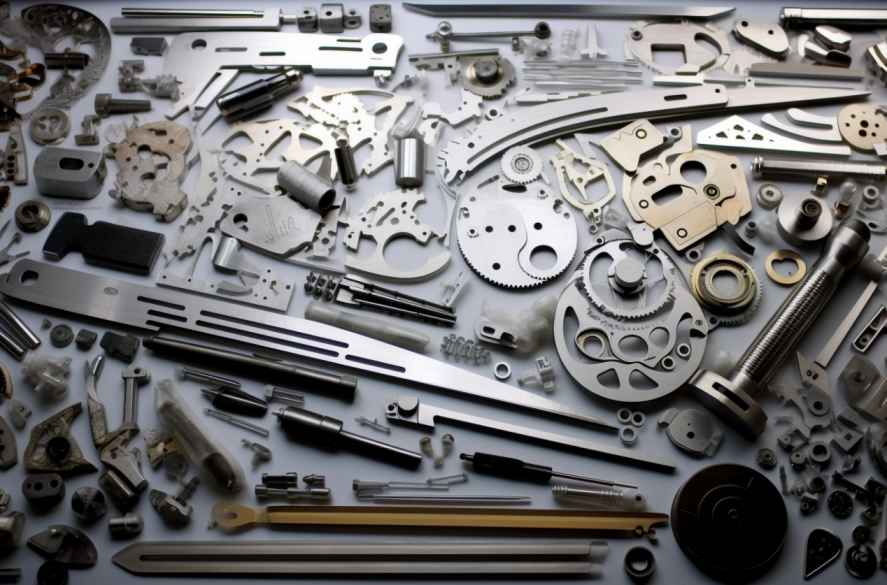

Metal Stamping Service: A Comprehensive Overview

Delve into the essential aspects of metal stamping services, including common materials, quality assurance, and finding the right provider for your project. Discover the importance of experience, capabilities, and technology when selecting a supplier like Louis Machine for precise and efficient metal stamping results.

Introduction

1.1 Introduction to Metal Stamping Services

Metal stamping services play a crucial role in modern manufacturing by enabling the shaping of metal sheets into a variety of forms and designs. This process involves the use of specialized dies and punches to shape the metal, resulting in components that can be utilized in various industries such as automotive, electronics, and consumer goods.

1.2 What is Metal Stamping?

Metal stamping is a manufacturing process that involves shaping metal sheets using a combination of dies and punches. The process works by placing a sheet of metal into a stamping press, which then shapes the metal through a series of movements and the application of pressure. The process can produce intricate designs and complex shapes, making it a popular choice for various industries.

1.3 Common Applications Across Industries

Metal stamping is used in a wide range of industries, including:

a. Automotive: Metal stamping produces parts such as brackets, panels, and frames for vehicles.

b. Electronics: Components such as connectors and housings for electronic devices are made using metal stamping.

c. Consumer Goods: The process is used to create parts for appliances, furniture, and other household items.

Advantages of Metal Stamping

Metal stamping offers several advantages that make it a preferred choice for manufacturers across industries.

2.1 Cost-effective Production

Metal stamping is a cost-effective method for producing large quantities of parts. Once the initial setup is complete, the process can be repeated quickly, reducing the cost per part.

2.2 High Precision and Repeatability

The use of precision dies and punches ensure that each part is consistent and meets the required specifications. This high level of repeatability is essential for industries such as automotive and electronics, where precision is crucial.

2.3 Complex Shapes and Intricate Designs

Metal stamping can produce complex shapes and intricate designs that would be difficult or impossible to achieve with other manufacturing methods. This allows manufacturers to create innovative and unique products.

2.4 Customization Options

Metal stamping services can be customized to meet the specific needs of different projects. Suppliers like Louis Machine offer a range of options for various materials, designs, and finishes, allowing manufacturers to tailor their products to their exact specifications.

Types of Metal Stamping Processes

There are several types of metal stamping processes, each with its own unique advantages and applications.

3.1 Progressive Stamping

Progressive stamping involves multiple stamping operations in one die, allowing for high efficiency and precision. The metal sheet is fed through the die, where each station performs a specific operation. This process is ideal for producing large quantities of parts quickly and accurately.

3.2 Transfer Stamping

Transfer stamping involves moving parts between different stations to complete complex parts. Each station performs a specific operation, such as bending or forming, before the part is transferred to the next station. This process is suitable for creating intricate parts with multiple features.

3.3 Four-Slide Stamping

Four-slide stamping, also known as multislide stamping, is ideal for intricate, multi-bend designs. The process uses four slides to manipulate the metal from different angles, allowing for the creation of complex shapes and forms. This method is often used for producing small, intricate parts.

3.4 Deep Draw Stamping

Deep draw stamping is a process that is suitable for creating deep, hollow parts. The process involves pulling a flat sheet of metal into a die cavity using a punch. Deep draw stamping is commonly used in industries such as automotive and consumer goods to create parts such as cups, cans, and enclosures.

Materials Used in Metal Stamping

5.1 Common Materials

Metal stamping utilizes a variety of materials depending on the project requirements. Common materials include:

a. Steel: Known for its strength and versatility, steel is widely used in metal stamping to create parts for industries such as automotive and construction.

b. Aluminum: Aluminum’s lightweight and corrosion-resistant properties make it a popular choice for parts in the aerospace and electronics industries.

c. Brass: Brass offers good electrical conductivity and is often used in electrical components and decorative items.

d. Copper: Copper’s excellent conductivity and malleability make it a key material for electrical and electronic applications.

5.2 Specialty Materials

In addition to the common materials, metal stamping also utilizes specialty materials for specific industry applications. These include:

a. Stainless Steel: Known for its corrosion resistance, stainless steel is used in industries such as medical, food processing, and automotive.

b. Titanium: Titanium’s high strength-to-weight ratio and corrosion resistance make it suitable for aerospace, medical, and military applications.

5.3 Factors to Consider When Selecting Materials

When choosing materials for metal stamping projects, several factors should be considered:

a. Mechanical properties: Choose materials with appropriate strength, ductility, and hardness for the specific application.

b. Corrosion resistance: Consider the environmental conditions the part will be exposed to and choose materials with adequate resistance.

c. Cost: Balance material costs with performance requirements to achieve cost-effective production.

Quality Assurance and Standards

6.1 Importance of Quality Control in Metal Stamping

Quality control is essential in metal stamping to ensure the production of accurate and consistent parts. This is particularly important for industries such as automotive and electronics, where precision is critical.

6.2 Industry Standards and Certifications

Metal stamping providers adhere to industry standards and certifications to maintain quality and consistency. Common standards include:

a. ISO: ISO certifications ensure that a provider follows international standards for quality management.

b. ASTM: ASTM standards specify the quality and testing requirements for materials and parts.

6.3 Inspecting and Testing Stamped Parts

Providers like Louis Machine employ rigorous inspection and testing processes to ensure stamped parts meet specifications. These processes may include:

a. Dimensional inspections: Using precision measuring tools to verify part dimensions.

b. Material testing: Checking material properties to ensure they meet industry standards.

c. Functional testing: Evaluating the part’s performance in real-world conditions.

Choosing a Metal Stamping Service Provider: Key Factors to Consider

7.1 When choosing a metal stamping service provider, consider the following factors:

a. Experience: Look for providers with a proven track record in the industry.

b. Capabilities: Ensure the provider has the equipment and expertise to handle your specific project requirements.

c. Technology: Advanced technology can lead to higher precision and efficiency in metal stamping.

7.2 Collaborative Approach and Excellent Customer Service

A collaborative approach between the provider and the client ensures clear communication and a better understanding of project needs. Excellent customer service is also crucial, as it leads to a smoother project execution and resolution of any potential issues.

7.3 Case Studies and Examples

Reviewing case studies and examples of successful projects can provide insight into a provider’s capabilities and expertise. Look for projects similar to your own to gauge the provider’s ability to meet your needs.

7.4 Requesting Quotes and Evaluating Providers

When requesting quotes, provide detailed information about your project to receive accurate estimates. Evaluate providers based on their responses, including pricing, lead times, and the level of service offered.

Conclusion

Metal stamping services offer a range of benefits, including cost-effective production, high precision, and the ability to produce complex shapes and intricate designs. With various types of metal stamping processes available, manufacturers can choose the best method for their specific project needs. Suppliers like Louis Machine provide expertise and customization options to help manufacturers achieve their goals and create high-quality products.