Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Advanced Mold Design and Manufacturing Technology: Let’s Dive Now

Mold design and manufacturing are indispensable to contemporary industrial production, enabling the creation of intricate and highly precise components utilized in a myriad of applications. At the core of this process lies the exceptional expertise and state-of-the-art technology embodied by companies like Louis Machine, a leader in the realm of high-precision mold making.

This blog delves into the fundamental aspects of mold design and manufacturing, elucidates the detailed steps involved, examines the numerous advantages of this method, and underscores the significant benefits of collaborating with Louis Machine. Whether you’re in consumer electronics or automotive parts, understanding these processes can provide a competitive edge in quality and efficiency.

What is Mold Design and Manufacturing?

Understanding Mold Design

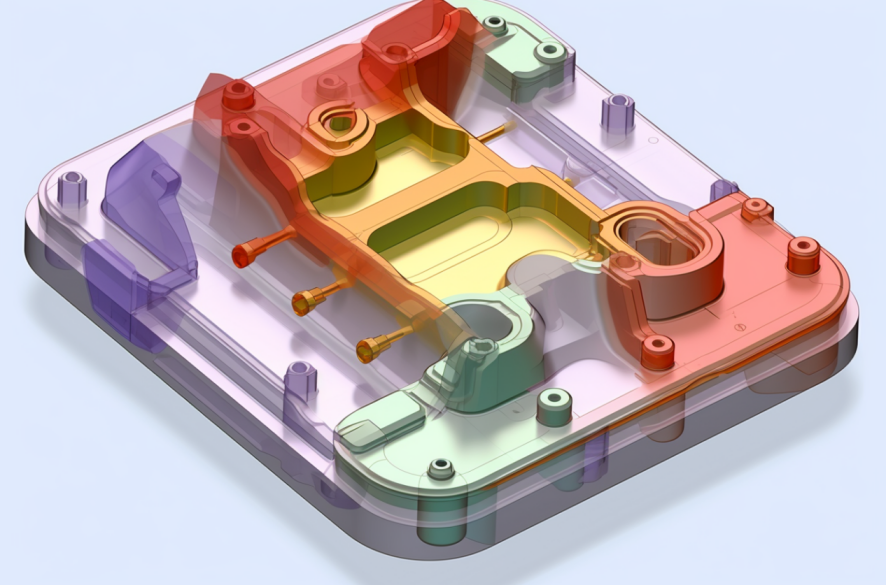

Mold design involves creating detailed plans for molds used to shape materials into specific forms. This process starts with a thorough analysis of the product requirements, including dimensions, material properties, and functional specifications. Advanced software tools are utilized to develop 3D models and simulations, ensuring the mold will produce parts with high precision and quality.

The Manufacturing Process

Manufacturing the mold involves several steps: selecting suitable materials, machining, and assembling. High-precision equipment, such as CNC machines, wire EDM, and grinding machines, are employed to shape the mold components. Each part of the mold must meet exact specifications to ensure the final product’s quality and consistency.

Applications of Mold Design and Manufacturing

Mold design and manufacturing are essential in various industries, including consumer electronics, automotive, medical devices, and more. They enable the mass production of intricate parts with consistent quality, making them indispensable in modern manufacturing.

How to Make Mold Design and Manufacturing

Initial Concept and Design

The process begins with understanding the client’s needs and the product’s intended function. Engineers at Louis Machine collaborate closely with clients to gather all necessary information and create an initial concept. This stage involves brainstorming, sketching, and preliminary 3D modeling to visualize the final product.

Detailed Engineering and Simulation

Once the initial design is approved, detailed engineering work begins. This includes creating comprehensive CAD models and running simulations to test the design under various conditions. These simulations help identify potential issues and optimize the design before moving to the manufacturing stage.

Precision Manufacturing and Assembly

The manufacturing phase utilizes advanced CNC machining, wire EDM, and other precision tools to create the mold components. Each piece is meticulously crafted and inspected to ensure it meets the exacting standards required for high-precision molds. After machining, the components are assembled and tested to verify their performance.

Why Choose Mold Design and Manufacturing?

Unmatched Precision and Quality

Mold design and manufacturing offer unparalleled precision, allowing for the creation of parts with tight tolerances and intricate details. This level of accuracy is essential for industries where even the smallest deviations can impact performance and safety.

Cost-Effective Mass Production

Once a mold is created, it can be used to produce thousands or even millions of parts, making it a cost-effective solution for mass production. This efficiency reduces the per-unit cost and ensures consistent quality across all produced parts.

Versatility and Customization

Mold design and manufacturing are highly versatile, capable of producing parts from various materials, including plastics and metals. This flexibility allows manufacturers to tailor the molds to specific requirements, providing customized solutions for different applications.

What Our Experience Can Do For You

Advanced Technology and Equipment

Louis Machine continually invests in high-precision equipment from Germany, Switzerland, and Japan, ensuring the latest technological advancements are at their disposal. This commitment to technology enables them to produce molds with exceptional accuracy and efficiency.

Expertise and Innovation

With years of accumulated experience, Louis Machine’s team of senior engineers excels in both traditional and innovative mold design techniques. Their expertise ensures that every mold meets the highest standards of quality and performance.

Comprehensive Quality Control

Louis Machine’s rigorous quality control system includes a materials laboratory accredited by CNAS. Every mold steel is strictly tested, and samples and testing reports are maintained for at least two years. This commitment to quality ensures that every mold produced meets the strictest standards.

Processing Advantages

Strong Manufacturing Capacity

Louis Machine’s robust manufacturing capacity is supported by over 130 sets of large-scale equipment, covering a total area of 30,500 m2. This infrastructure enables them to handle large volumes and complex projects efficiently.

Excellent Precision Control

The experienced processing team at Louis Machine can achieve grinding accuracy at the sub-micron level, with CNC processing capable of reaching ±0.002mm. Their wire EDM and electric spark EDM processes can achieve accuracies of ±0.001mm and ±0.003mm, respectively, ensuring the highest precision in every mold.

A Highly Trained Technical Team

Louis Machine boasts a team of engineers with several decades of experience in mold design and manufacturing. Their deep understanding of the process allows them to provide the best process analysis and solutions, ensuring each project is executed flawlessly.

Quality Control System

Rigorous Testing and Certification

Louis Machine’s quality control system is backed by a materials laboratory accredited by the national department (CNAS). This ensures that all mold steels are rigorously tested and certified, providing clients with confidence in the quality and durability of their molds.

Long-Term Sample Retention

To maintain high standards and traceability, Louis Machine keeps samples and testing reports for at least two years. This practice ensures that any issues can be traced back to their source, facilitating continuous improvement and client satisfaction.

Commitment to Excellence

Louis Machine’s dedication to quality is evident in every aspect of their operation, from initial design to final production. This commitment ensures that every mold they produce meets the highest standards of performance and reliability.

About Louis Machine

A Legacy of Precision and Innovation

Founded in March 2011 through the merger of two precision mold and hardware product factories, Louis Machine has established itself as a leader in mold design and manufacturing. Located in Shenzhen, one of China’s most dynamic cities, the company specializes in auto parts, plastic products injection, precision parts, and mold production.

Diverse Capabilities

Louis Machine comprises several specialized factories, including a precision plastic mold factory, a precision hardware products factory, an automotive metal products factory, and a Hong Kong branch. This diverse expertise allows them to cater to a wide range of industries and applications.

A Commitment to Excellence

With a total area of 30,500 m2 and over 130 sets of major large-scale equipment, Louis Machine is well-equipped to handle projects of any scale and complexity. Their ongoing investment in technology, talent, and quality control ensures they remain at the forefront of the mold design and manufacturing industry.

Conclusion

In conclusion, mold design and manufacturing are critical to producing high-precision parts used in various industries. Louis Machine’s advanced technology, experienced team, and rigorous quality control make them a trusted partner in this field. By choosing Louis Machine, clients can expect exceptional precision, quality, and service, ensuring their projects’ success.