Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

How to Choose the Best Mold Manufacturer for Your Needs

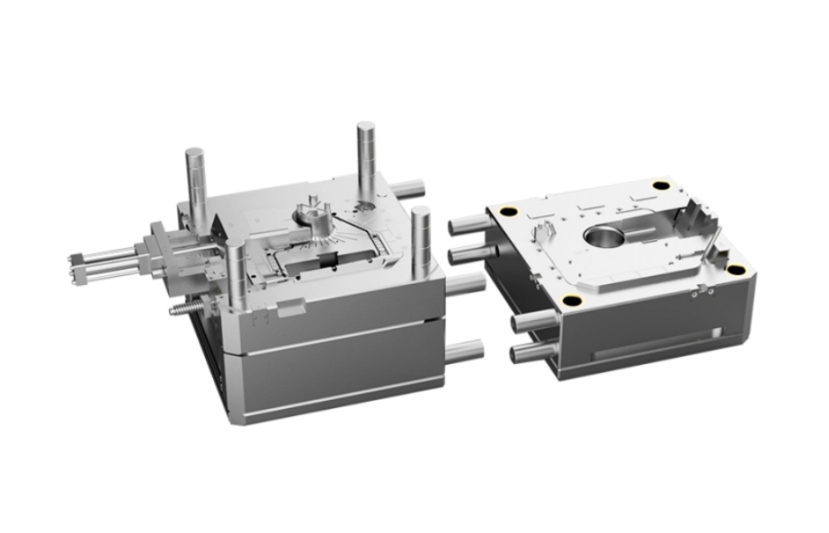

A mold manufacturer designs and produces molds for various industries to create precision parts. Louis Machine, a leading name in this field, is renowned for its high precision and quality. By introducing advanced equipment from Germany, Switzerland, and Japan, and hiring senior engineers, they stay at the forefront of innovation. Specializing in precision injection molds, plastic parts, and high precision metal parts, Louis Machine ensures top accuracy and reliability with decades of experience and rigorous quality control.

What is a Mold Manufacturer?

A mold manufacturer is a specialized company that designs, engineers, and produces molds used in the manufacturing process. These molds are critical tools in industries like consumer electronics, automotive, medical devices, and more, facilitating the mass production of precision plastic and metal parts. Mold manufacturers use advanced machinery and technology to create molds that meet stringent specifications, ensuring that the final products are of the highest quality.

Louis Machine is a leading name in mold manufacturing, known for its high precision and commitment to excellence. The company continues to introduce a variety of high precision equipment, hire senior engineers, and develop advanced technology and management concepts. This approach has positioned Louis Machine as a trusted partner in the industry.

How to Find the Best Mold Manufacturer

Finding the best mold manufacturer can be a daunting task, given the critical role they play in production. Here are key considerations to help identify a top-tier mold manufacturer like Louis Machine.

Evaluate Technical Expertise and Experience

The first step is to assess the technical expertise and experience of the manufacturer. Louis Machine, for example, boasts decades of experience and a team of highly trained engineers. Their extensive knowledge in design and manufacturing ensures that they can handle complex projects with precision.

Inspect the Equipment and Technology

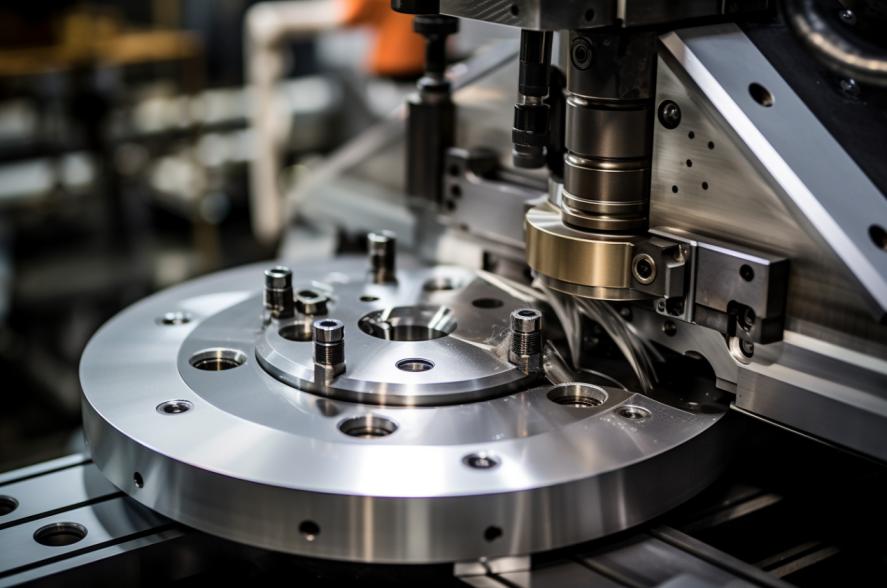

The quality of the molds produced is heavily dependent on the equipment and technology used. Louis Machine continues to invest in high-end equipment from Germany, Switzerland, and Japan. Their advanced CNC machine tools and precision control capabilities allow them to achieve grinding accuracy at the sub-micron level, ensuring superior quality.

Check Quality Control Processes

Quality control is paramount in mold manufacturing. A reputable manufacturer like Louis Machine will have rigorous quality control systems in place. They have established materials laboratories and obtained CNAS accreditation, ensuring all mold steels are strictly tested and documented. This meticulous approach guarantees that every mold meets high standards of precision and durability.

What Mold Manufacturers Can Provide

Mold manufacturers offer a range of services and products essential for various industries. Here’s what you can expect from a top-tier mold manufacturer like Louis Machine.

Precision Injection Molds and Plastic Parts

Louis Machine specializes in creating precision injection molds and plastic parts. These components are vital in industries such as consumer electronics, where accuracy and quality are non-negotiable. Their molds are designed to produce parts that meet exact specifications, ensuring consistency in mass production.

High Precision Metal Parts

In addition to plastic parts, Louis Machine excels in manufacturing high precision metal parts. These parts are crucial in sectors like automotive and aerospace, where even the smallest deviations can have significant consequences. With their advanced machining capabilities, Louis Machine can produce metal parts with exceptional accuracy.

Customized Solutions for Various Industries

Louis Machine understands that different industries have unique requirements. They offer customized solutions tailored to specific needs, whether it’s for smart wearable products, electronic communication precision parts, or personal electronic device connector assemblies. Their ability to provide bespoke solutions sets them apart in the industry.

What Our Experience Can Do For You

Louis Machine’s extensive experience in mold manufacturing brings numerous benefits to its clients. Here’s how their expertise can make a difference.

Innovative Technology and Advanced Equipment

Louis Machine’s continuous investment in innovative technology and advanced equipment ensures it stays ahead of industry trends. This commitment allows them to produce high-quality molds that meet the evolving demands of their clients. Their state-of-the-art machinery from Germany, Switzerland, and Japan ensures precision and efficiency in every project.

Highly Skilled Technical Team

The strength of Louis Machine lies in its highly skilled technical team. With several decades of working experience, their engineers are adept at conducting thorough process analyses and providing optimal solutions. This expertise ensures that every project is executed flawlessly, from initial design to final production.

Stringent Quality Control

Quality is at the heart of everything Louis Machine does. Their stringent quality control systems guarantee that every mold and part produced meets the highest standards. By establishing a materials laboratory and obtaining CNAS accreditation, they ensure that all materials and processes are thoroughly tested and documented. This rigorous approach provides clients with the assurance that they are receiving top-quality products.

Strong Manufacturing Capacity

Louis Machine’s strong manufacturing capacity is a testament to their ability to handle large-scale projects efficiently. Their high-end equipment and experienced team enable them to produce molds and parts with exceptional precision and speed. This capacity allows them to meet the demands of various industries, from consumer electronics to automotive and beyond.

Advanced CNC Machine Tools

The core of Louis Machine’s manufacturing prowess lies in its advanced CNC machine tools. These tools, sourced from leading manufacturers in Germany, Switzerland, and Japan, provide unparalleled precision. With capabilities such as sub-micron level grinding accuracy and tight tolerance machining, Louis Machine can deliver parts that meet the most stringent specifications.

Efficient Production Processes

Efficiency is key to Louis Machine’s manufacturing success. Their well-organized production processes ensure that projects are completed on time and within budget. This efficiency, combined with their technical expertise, allows them to provide high-quality products without compromising on speed or cost.

Excellent Precision Control

Precision control is a critical aspect of mold manufacturing, and Louis Machine excels in this area. Their experienced processing team and advanced equipment enable them to achieve remarkable accuracy in every project.

Sub-Micron Level Grinding Accuracy

Achieving sub-micron level grinding accuracy is a hallmark of Louis Machine’s capabilities. This precision ensures that every mold and part produced meets exact specifications, which is essential for industries that demand high accuracy.

Tight Tolerance Machining

Louis Machine’s CNC processing centers can reach tolerances of +/- 0.002mm, while their wire cutting and EDM capabilities can achieve tolerances as tight as +/- 0.001mm and +/- 0.003mm, respectively. These tight tolerances ensure that the parts produced are consistent and reliable.

A Highly Trained Technical Team

The expertise of Louis Machine’s technical team is unmatched. Their engineers have decades of experience in design and manufacturing, providing clients with the best process analyses and solutions.

Comprehensive Process Analysis

Louis Machine’s engineers conduct comprehensive process analyses to identify the best manufacturing approach for each project. This thorough analysis ensures that the final product meets the client’s requirements while optimizing efficiency and cost.

Tailored Solutions for Complex Projects

The technical team at Louis Machine excels in providing tailored solutions for complex projects. Their extensive experience and innovative approach allow them to tackle challenging projects with ease, delivering exceptional results every time.

Quality Control System

Quality control is a cornerstone of Louis Machine’s operations. Their robust quality control system ensures that every product meets the highest standards of quality and reliability.

Accredited Materials Laboratory

Louis Machine has established an accredited materials laboratory, ensuring that all materials used in their manufacturing processes are rigorously tested and documented. This accreditation provides clients with confidence in the quality and durability of the products they receive.

Thorough Testing and Documentation

Every mold steel used by Louis Machine undergoes thorough testing and documentation. This meticulous approach ensures that all materials meet the necessary specifications and standards, providing clients with reliable and high-quality products.

Conclusion

Louis Machine stands out as a premier mold manufacturer, offering unparalleled precision, expertise, and quality. Their continuous investment in advanced technology, highly skilled technical team, and stringent quality control systems ensure that they deliver the best products and services to their clients. Whether you need precision plastic parts, high-precision metal parts, or customized solutions for complex projects, Louis Machine is the partner you can trust. Their extensive experience and commitment to excellence make them the ideal choice for all your mold manufacturing needs.