Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Why OEM/ODM Parts or Components Are Essential for Your Product’s Brand Integrity

In the highly competitive global marketplace, maintaining brand integrity is essential to ensure customer loyalty and long-term success. But what many companies may not realize is that the foundation of their brand’s reputation often rests on the quality and reliability of the parts and components that go into their products. This is where OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) components play a critical role. Choosing the right OEM/ODM Parts or Components partner not only strengthens your product’s quality but also enhances your brand’s overall integrity. Let’s explore why OEM/ODM Parts or Components are indispensable for your brand’s identity, using Louis Machine as a prime example of a high-quality provider in this space.

What Are OEM/ODM Parts or Components and Why Are They Important?

Understanding OEM and ODM Models

OEM and ODM are two distinct production models that serve different business needs. OEM parts are manufactured based on a company’s specific design and technical specifications, allowing full control over product quality. On the other hand, ODM components are pre-designed and produced by manufacturers but can be customized to align with a company’s branding needs. Both models offer unique advantages depending on the company’s goals and product lines.

Impact on Brand Integrity

Brand integrity is deeply rooted in product consistency and performance. When customers buy a product, they expect it to meet certain quality standards, reflecting the promises made by the brand. OEM/ODM parts ensure that these expectations are met by providing high-quality, reliable components that align with the brand’s identity. A failure in a key component, even if not visible to the end customer, can have devastating effects on the brand’s reputation. Reliable OEM/ODM partners like Louis Machine offer the peace of mind that every part used in production adheres to strict quality control standards.

High-Precision Manufacturing Technology at Louis Machine

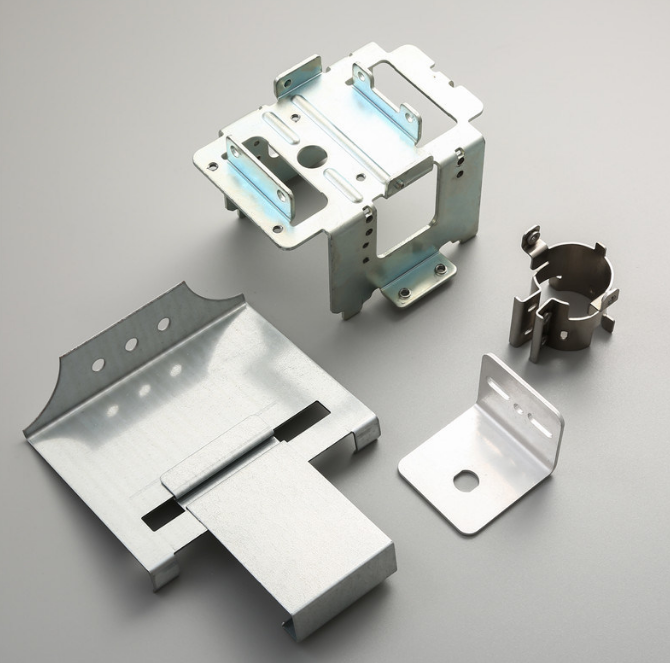

Louis Machine uses the most advanced CNC machining technologies and equipment, ensuring that their parts and components meet the highest standards of precision, efficiency, and stability. Whether your product requires metal hardware, plastic injections, or precision mold production, working with such a partner ensures that your brand maintains the integrity and consistency that customers expect.

How OEM/ODM Parts or Components Enhance Product Quality

Precision Engineering for High-Performance Products

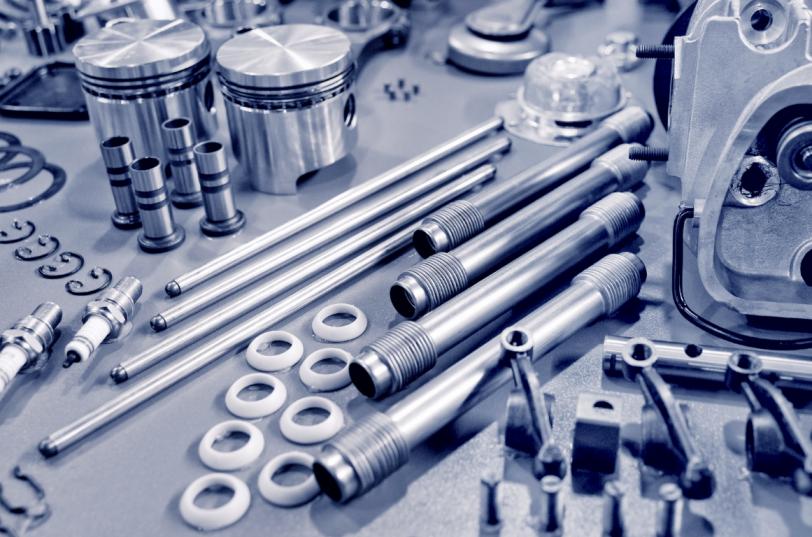

In today’s fast-paced and technology-driven market, precision is key. Products, especially in industries like automotive, electronics, and aerospace, require exacting specifications to ensure functionality and safety. Louis Machine’s equipment, including ZEISS and Hexagon CMMs (Coordinate Measuring Machines), ensures that each component meets the highest precision standards, with tolerances as tight as +/- 0.001mm in grinding and wire cutting, and similar tolerances for CNC machining and EDM processes.

Customized Solutions for Unique Product Requirements

No two brands are the same, and each has its own set of product requirements. That’s why Louis Machine offers fully customized solutions, allowing companies to develop parts tailored to their specific needs. Whether it’s a unique mold design or specialized plastic injection components, working with an OEM/ODM Parts or Components provider ensures that the products reflect the company’s vision, contributing to its brand’s uniqueness and competitive edge.

Quality Control and Testing: The Heart of Brand Integrity

Nothing erodes brand trust faster than poor-quality products. Louis Machine understands this, which is why they have implemented rigorous quality control processes. Their strong quality control department conducts thorough inspections, ensuring that all parts meet international standards, including ISO 9001:2015 certification. This commitment to quality testing and compliance assures brands that the components they source from Louis Machine will stand the test of time.

The Advantages of Partnering with Louis Machine

Full-Service OEM/ODM Parts or Components Capabilities

One of the major benefits of working with Louis Machine is their one-stop service model. From mold design and production to plastic injection and hardware manufacturing, they provide comprehensive solutions for companies in need of high-quality components. This full-service approach reduces the complexities of dealing with multiple suppliers, ensuring seamless integration of OEM/ODM Parts or Components into your product lines. Additionally, Louis Machine’s expertise in auto parts, plastic products, and precision mold production provides added value to companies in diverse industries.

Speed and Efficiency in Production

In today’s competitive market, time is often just as important as quality. With a fast response time and the ability to provide quotes within 24 hours, Louis Machine helps brands stay ahead of tight production schedules. Their streamlined processes ensure timely delivery of both samples and finished products, enabling companies to meet market demands without sacrificing quality. This efficiency also plays a critical role in scaling operations and launching new product lines on time.

Advanced Technology and Equipment for Cutting-Edge Manufacturing

Louis Machine continually invests in cutting-edge technology and equipment. This includes ROEDERS, MAKINO and SEIBU machines, ensuring they are always at the forefront of the industry. Their ability to perform mold flow analysis can detect and resolve potential issues such as warpage or weld lines in advance, ensuring product designs are executed perfectly. These advanced technologies not only improve product quality. They also increase manufacturing efficiency, resulting in cost savings that can be passed on to customers.

Scaling Your Business with OEM/ODM Partnerships

OEM vs. ODM: Which is Best for Scaling?

As companies grow, they often face a dilemma—should they opt for the OEM or ODM model to scale their business? OEM parts offer complete control over design and technical specifications, making it ideal for companies looking to protect their intellectual property and develop highly specialized products. ODM, on the other hand, allows for quicker time-to-market since the parts are pre-designed but customizable. Louis Machine offers both models, allowing businesses the flexibility to choose the best approach for their needs.

How OEM/ODM Components Drive Cost Efficiency

One of the major advantages of partnering with an experienced OEM/ODM supplier like Louis Machine is cost efficiency. By leveraging the expertise and infrastructure of specialist manufacturers. Companies can reduce overhead costs related to production, quality control and supply chain management. This allows businesses to focus on core operations such as marketing and sales. While ensuring that its products meet the highest quality standards.

Ensuring Brand Integrity in a Global Market

In an increasingly globalized market, maintaining brand integrity requires reliable partners who understand international standards and regulations. Louis Machine is committed to quality, efficiency and customization. They are a trusted partner for brands looking to expand their reach while maintaining the highest product integrity. Their experience working with clients around the world ensures that all components meet not only local standards. But also international compliance standards, protecting your brand’s reputation in every market.

Conclusion: Building a Strong Brand with the Right OEM/ODM Partner

Maintaining brand integrity requires more than just a great product design—it hinges on the quality of the components that bring your products to life. By partnering with a reputable OEM/ODM Parts or Components service provider like Louis Machine, companies can ensure that their products meet the highest standards of precision, quality, and reliability. Louis Machine has advanced technology, comprehensive service and a commitment to quality. The ideal partner for any company looking to maintain and enhance brand integrity. Ultimately, the quality of the parts you choose can make or break your brand’s reputation, and with Louis Machine. You can rest assured that your brand is in capable hands.