Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Why OEM Parts Made Matter: Ensuring High-Performance

OEM parts, or Original Equipment Manufacturer parts, are essential components designed to meet original brand specifications, ensuring compatibility and performance. Crucial in industries like consumer electronics, these parts require precision and reliability. Louis Machine excels as a leading supplier, using advanced manufacturing technologies and high-quality materials from Japan and Sweden. Their expertise in high-precision machining and mold flow analysis ensures each component meets rigorous standards, making Louis Machine a trusted partner in the industry.

Understanding OEM Parts Made

What are OEM Parts Made?

OEM stands for Original Equipment Manufacturer. OEM parts made are components that are made by one company and used in the products of another company, often the brand that sells the final product. These parts are typically designed and manufactured to meet the exact specifications and standards set by the original brand, ensuring compatibility and performance.

The Importance of OEM Parts

OEM parts play a critical role in various industries, including automotive, electronics, and consumer goods. Their importance lies in their quality and reliability. Since OEM parts are made to the original manufacturer’s specifications, they often offer better performance and longevity compared to aftermarket parts. This is particularly important in consumer electronics, where the precision and reliability of each component can significantly impact the overall product quality and user experience.

Examples of OEM Parts Made in Electronics

In the realm of consumer electronics, OEM parts can include components such as circuit boards, batteries, screens, and internal connectors. These parts are essential for the proper functioning of devices like smartphones, laptops, cameras, and drones. Using OEM parts ensures that these devices operate efficiently and safely, providing a seamless experience to the end-user.

Custom OEM Parts: Tailoring to Specific Needs

The Process of Custom OEM Parts

Creating custom OEM parts involves several stages, from initial design and prototyping to final production. The process begins with understanding the specific requirements of the client, including dimensions, materials, and functionality. Advanced CAD (Computer-Aided Design) software is used to create detailed models of the parts, which are then tested through simulations to ensure they meet all necessary standards.

Prototyping and Testing

Once the design phase is complete, prototypes are made using various methods such as 3D printing or CNC machining. These prototypes undergo rigorous testing to check for any defects or performance issues. This step is crucial as it allows for adjustments to be made before mass production begins, ensuring that the final product is of the highest quality.

Production and Quality Control

After successful prototyping, the production phase begins. High-precision manufacturing equipment is used to produce the parts in large quantities. Throughout the production process, strict quality control measures are in place to ensure that each part meets the required specifications. This includes regular inspections and testing to identify and address any issues promptly.

Louis Machine: Meeting Business Needs with Excellence

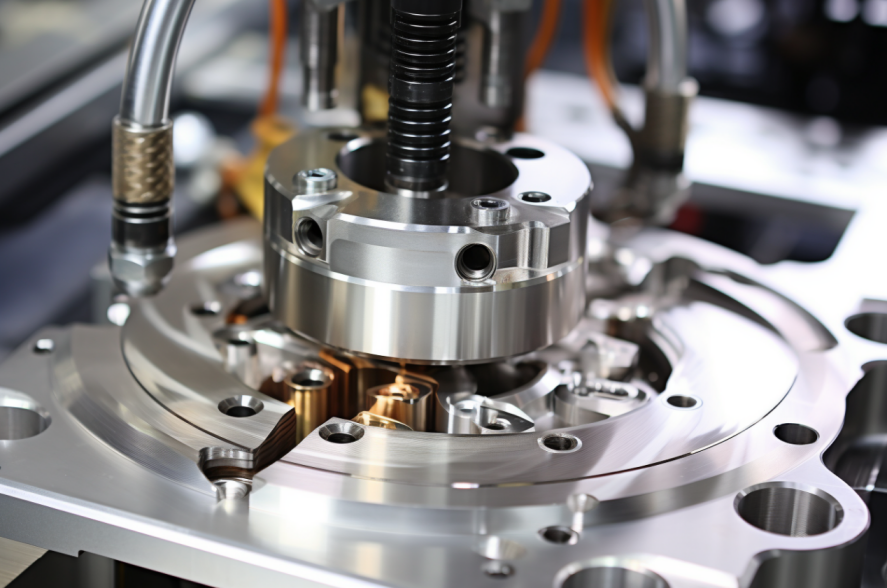

Advanced Manufacturing Capabilities

Louis Machine stands out as a leading supplier of OEM parts due to its advanced manufacturing capabilities. The company utilizes high-end equipment from renowned brands like German ROEDERS and Japanese MAKINO, ensuring the highest machining accuracy. Their precision equipment can achieve tolerances as fine as + / -0.001mm, making them ideal for producing complex and high-precision electronic components.

Superior Material Quality

The quality of the materials used is another critical factor in the success of Louis Machine’s OEM parts. The company imports mold steels from top suppliers like Japan Datong and Sweden Uddeholm/ASSAB. These steels are known for their excellent wear resistance, deformation resistance, and polishing performance. By using superior materials, Louis Machine ensures that its parts are not only durable but also perform exceptionally well under various conditions.

Expertise in Mold Flow Analysis

One of the unique strengths of Louis Machine is its expertise in Mold Flow Analysis. This advanced technique allows the company to simulate the injection molding process and predict potential issues such as warpages and weld lines. By addressing these problems early in the design phase, Louis Machine can produce parts with complex structures and high accuracy, minimizing defects and ensuring optimal performance.

Applications in Consumer Electronics

Electronic Product Accessories

Louis Machine’s OEM parts are widely used in various electronic product accessories. These include components for smartphones, tablets, and other portable devices. The precision and quality of these parts are crucial in ensuring the reliability and performance of the final products, providing consumers with a seamless and satisfying user experience.

Digital Camera Parts

In the realm of digital cameras, the precision of OEM parts is paramount. Louis Machine produces high-quality components such as lens mounts, sensor housings, and internal connectors. These parts must meet exact specifications to ensure the camera functions correctly, providing users with clear, high-resolution images.

Unmanned Aerial Vehicle (UAV) Parts

The growing popularity of drones and UAVs has increased the demand for high-precision OEM parts in this field. Louis Machine supplies components such as motor mounts, camera gimbals, and flight control housings. These parts are designed to be lightweight yet durable, ensuring the UAVs perform optimally in various environments.

Innovate, Disrupt, Excel: The Core Technologies

Commitment to Innovation

At the heart of Louis Machine’s success is its commitment to innovation. The company continually invests in new technologies and processes to stay ahead of the competition. This includes adopting the latest CAD software, advanced machining techniques, and state-of-the-art quality control systems. By fostering a culture of innovation, Louis Machine ensures that its OEM parts remain at the forefront of the industry.

Disruptive Technologies

Louis Machine leverages disruptive technologies to enhance its manufacturing processes. This includes the use of AI and machine learning to optimize production lines, predictive maintenance to reduce downtime, and IoT-enabled devices for real-time monitoring and control. These technologies not only improve efficiency but also ensure the highest quality standards are maintained throughout the production process.

Excellence in Execution

Excellence in execution is a core value at Louis Machine. From the initial design to the final production, every step is meticulously planned and executed to ensure the best possible outcome. The company’s skilled workforce, combined with its advanced equipment and stringent quality control measures, guarantees that every part produced meets the highest standards of quality and reliability.

Conclusion: A Partner for Success

In a rapidly evolving world of technology, consumer electronics have become an integral part of modern life. Louis Machine, as a leading supplier of OEM parts, is committed to providing diversified, innovative, and high-quality components to meet the ever-growing demands of this industry. Whether it’s electronic product accessories, digital camera parts, or UAV components, Louis Machine’s expertise and advanced capabilities make it the ideal partner for any business looking to excel in the consumer electronics market.

For businesses seeking reliable and high-quality OEM parts, Louis Machine offers a comprehensive solution that combines advanced technology, superior materials, and a commitment to excellence. With a focus on innovation and precision, Louis Machine ensures that every part it produces contributes to the success and satisfaction of its clients. Innovate, disrupt, excel – this is the heartbeat of Louis Machine’s core technologies and the foundation of its success in the competitive world of consumer electronics.