Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

How One Stop Manufacturing Services Can Reduce Lead Times and Boost Output

Imagine this: you’re a manufacturer racing against time to bring a new product to market. Every day you delay means lost revenue, frustrated customers, and potentially falling behind competitors. Now, imagine cutting those delays in half while simultaneously boosting production capacity. Sounds like a dream? Not with One Stop Manufacturing Services. By integrating multiple stages of production under one roof, these services can reduce lead times and significantly enhance output. But how does it work? And what does a company like Louis Machine bring to the table? Let’s dive in.

What Is One Stop Manufacturing?

One Stop Manufacturing refers to a comprehensive approach that consolidates multiple stages of product development—from design and prototyping to mass production and assembly—within a single facility. This seamless integration eliminates the need for multiple suppliers, ensuring better coordination, faster production, and improved quality control.

At Louis Machine, the philosophy of One Stop Manufacturing is at the core of its operations. With a range of high-precision equipment, expert engineers, and cutting-edge management techniques, Louis Machine has revolutionized the production process for clients across industries like consumer electronics, automotive parts, and more.

Reducing Lead Times: The Louis Machine Advantage

Consolidated Processes for Efficiency

One of the biggest bottlenecks in traditional manufacturing is the time spent transferring designs, parts, and products between different suppliers. At Louis Machine, all aspects of production happen in-house, from initial prototyping to the final assembly. This not only streamlines production but also eliminates delays caused by outsourcing parts of the process.

For instance, when working with multiple suppliers, you may face unforeseen delays in shipping, miscommunication about product specifications, or quality control issues. Louis Machine removes these inefficiencies by handling everything under one roof.

With their high-end equipment sourced from Germany, Switzerland, and Japan, Louis Machine can manage the most complex production challenges with speed and precision. By doing so, clients are able to dramatically cut down lead times, allowing them to bring their products to market faster than ever before.

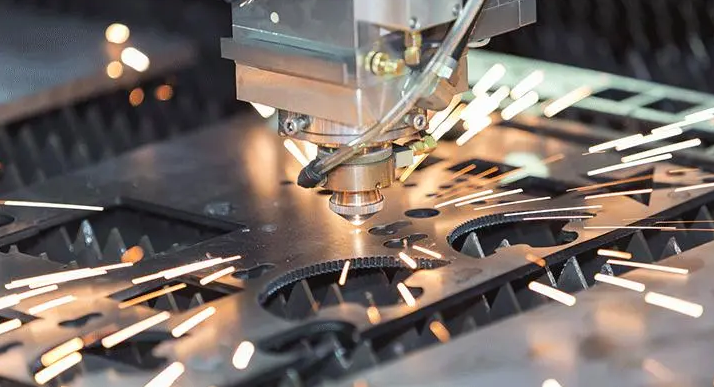

Advanced Equipment and Technology

Another key factor in reducing lead times is the use of cutting-edge technology. Louis Machine continually invests in state-of-the-art equipment and stays up-to-date with the latest advances in manufacturing technology. This allows for quicker turnaround times, as these machines can complete tasks faster and more accurately than traditional methods.

For example, Louis Machine’s CNC machining centers can achieve tolerances as precise as ±0.002mm, and their wire cutting and electric spark EDM technologies boast accuracies of ±0.001mm and ±0.003mm, respectively. These high-precision tools ensure that each part is made right the first time, reducing the need for costly reworks or delays.

Highly Trained Technical Team

In addition to equipment, human expertise plays a vital role in reducing lead times. Louis Machine boasts a team of experienced engineers with decades of hands-on experience in mold making, precision machining, and design. This technical expertise enables them to foresee potential issues before they become problems, ensuring smoother production flows.

Their engineers are skilled at making the best process analysis, allowing for quicker decision-making and more efficient use of resources. By leveraging their technical knowledge, Louis Machine is able to further accelerate production timelines.

Boosting Output: Maximizing Production with One Stop Manufacturing Services

Strong Manufacturing Capacity

One Stop Manufacturing is not just about speed—it’s about scalability. Louis Machine has developed a strong manufacturing capacity by continually expanding its facilities and acquiring cutting-edge equipment. With a factory space of over 30,500 square meters and more than 130 major large-scale machines, they can handle high-volume production runs without compromising quality.

Whether it’s producing precision hardware parts for consumer electronics or manufacturing automotive metal components, Louis Machine can manage large-scale orders efficiently. This capacity ensures that no matter how big or complex the order, production lines keep running smoothly, and output remains high.

Precision Control for Consistent Quality

While increasing output, maintaining consistent quality is critical. At Louis Machine, quality control is never sacrificed for speed. The company has established a comprehensive materials laboratory and adheres to strict testing protocols. They have even obtained accreditation from CNAS, China’s national accreditation service, which speaks to their commitment to quality.

Each part that comes out of their factory goes through rigorous testing, ensuring it meets the exact specifications required. By using precise equipment like CNC machines and EDM systems, Louis Machine is able to maintain tight tolerances while boosting production output, ensuring every product that leaves the facility is flawless.

This precision is especially important for industries that rely on high-performance components, such as consumer electronics and automotive manufacturing. Louis Machine’s ability to produce high volumes while keeping quality standards at the highest level is a testament to its superior capabilities.

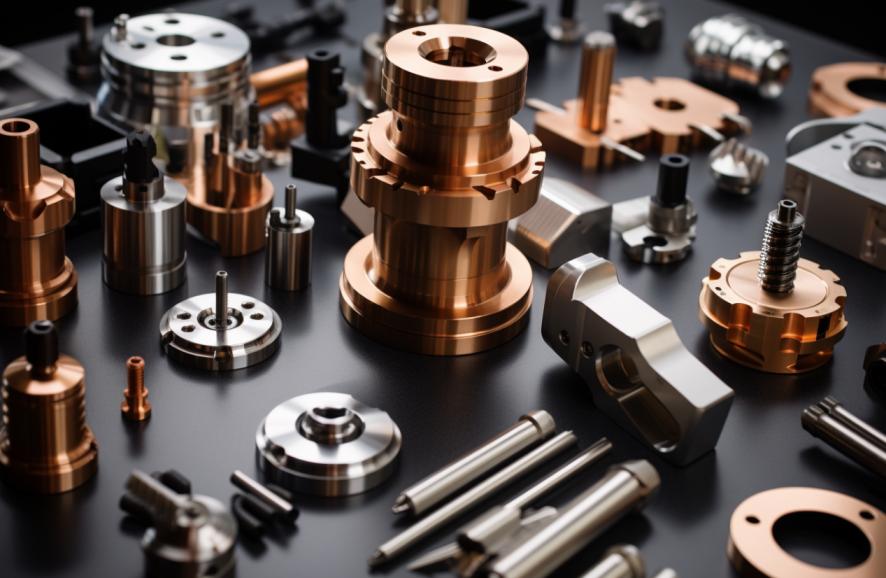

Advanced Materials and Technologies

Another key factor in boosting output is the ability to work with a wide variety of materials, including metals, plastics, and composites. Louis Machine’s versatility enables them to serve clients from diverse industries, offering customized solutions that meet the specific needs of each project.

Their expertise in handling materials like aluminum-magnesium alloy for engine shells, precision plastic injection molds, and other complex materials sets them apart from competitors. By staying at the forefront of material science and technology, Louis Machine can optimize production processes, reduce material waste, and maximize output without sacrificing quality.

Louis Machine: A Partner You Can Trust

Comprehensive Services for Every Industry

Whether your project involves creating intricate components for personal electronic devices, high-precision molds for smart wearable products, or metal parts for automotive applications, Louis Machine’s One Stop Manufacturing Services have the flexibility and capacity to meet your needs.

Their experience in working across multiple industries has made them a trusted partner for companies looking to improve production efficiency and reduce lead times. By centralizing all production processes, Louis Machine can offer end-to-end solutions that cover everything from design and prototyping to mass production and final assembly.

A Commitment to Innovation and Excellence

What sets Louis Machine apart from other manufacturers is their commitment to continuous improvement. They are constantly introducing new equipment, hiring top engineers, and adopting advanced technologies. This commitment to innovation ensures that clients always receive the best possible service and the highest-quality products.

Since its establishment in 2011, Louis Machine has grown into a leading player in the manufacturing industry, known for their precision, efficiency, and reliability. By choosing Louis Machine as your manufacturing partner, you can trust that your project is in capable hands.

Conclusion: The Future of Manufacturing Is Here

As the pace of innovation accelerates, so does the need for faster, more efficient manufacturing processes. One Stop Manufacturing Services like those offered by Louis Machine are transforming the industry by reducing lead times and boosting output. By consolidating production processes, using advanced technologies, and employing a highly skilled technical team, Louis Machine helps companies stay ahead in an increasingly competitive marketplace.

If you’re looking for a manufacturing partner that can deliver high-quality products quickly and efficiently, Louis Machine’s One Stop Manufacturing Services offer the perfect solution.