Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

What do You Know about Precision Plastic Products Manufacturer?

Precision plastic products manufacturer like Louis Machine specializes in precision plastic products manufacturing, offering expertise in injection molding and quality control. With a focus on innovation and excellence, we deliver custom solutions for various industries. From automotive to medical and electronics, our precision-engineered products meet the highest standards of accuracy and reliability. With advanced techniques and stringent quality assurance measures, we ensure consistent results and customer satisfaction. Trust Louis Machine for all your precision plastic product needs.

Introduction to Precision Plastic Products Manufacturing

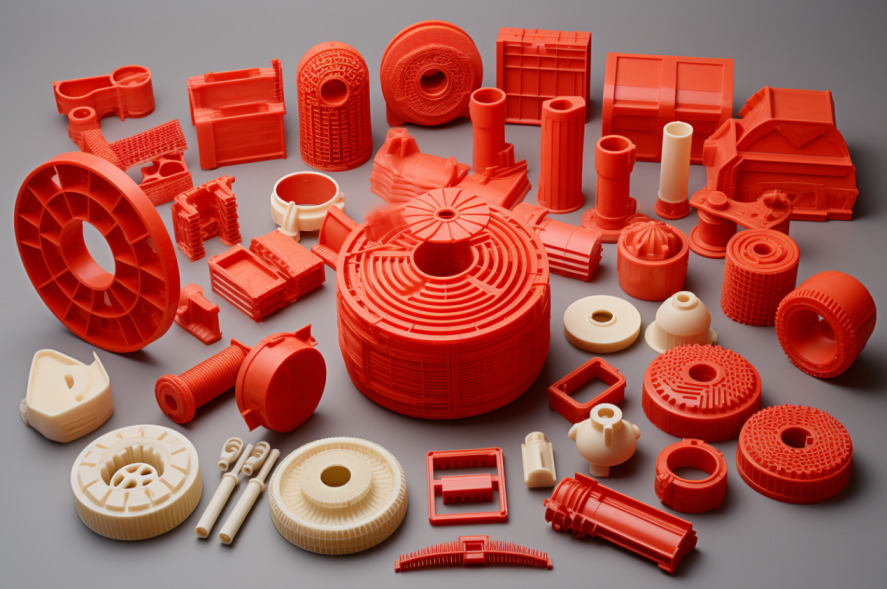

Precision plastic products play a pivotal role in various industries, from automotive to electronics, healthcare to consumer goods. These products, meticulously designed and manufactured, offer high accuracy, durability, and reliability. At the forefront of this intricate process stands Louis Machine, a leading manufacturer renowned for its precision engineering and innovative solutions.

1.1 Defining Precision Plastic Products

Precision plastic products refer to components or parts fabricated with utmost accuracy and consistency. These items often require tight tolerances and intricate designs to meet specific functional and aesthetic requirements.

1.2 The Manufacturing Process

Precision plastic product manufacturing involves several stages, including design, material selection, tooling, injection molding, and quality assurance. Each step demands meticulous attention to detail and expertise to ensure the final product’s precision and quality.

1.3 Importance of Precision

Precision is paramount in plastic product manufacturing as it directly influences product performance, reliability, and customer satisfaction. Even minor deviations can lead to functionality issues or product failure, emphasizing the critical role of precision in this industry.

Materials Used in Precision Plastic Products

Precision plastic products manufacturer like Louis Machine utilizes a range of materials tailored to meet diverse application needs, each offering unique properties and advantages.

2.1 ABS (Acrylonitrile Butadiene Styrene)

ABS is a versatile thermoplastic known for its high impact resistance and durability. It finds applications in automotive components, electronic enclosures, and consumer goods due to its excellent strength-to-weight ratio and moldability.

2.2 Polycarbonate

Polycarbonate boasts exceptional optical clarity, high heat resistance, and impact strength, making it ideal for products requiring transparency and toughness. Louis Machine leverages polycarbonate for manufacturing medical devices, safety equipment, and electronic housings.

2.3 Acrylic (PMMA)

Acrylic combines optical clarity with weather resistance, making it a popular choice for applications demanding aesthetics and durability. Louis Machine utilizes acrylic for signage, display cases, and lighting fixtures, leveraging its versatility and aesthetic appeal.

2.4 Advancements in Material Selection

Recent advancements in polymer science have led to the development of novel materials with enhanced properties, such as improved heat resistance, chemical resistance, and biocompatibility. Louis Machine stays abreast of these trends to offer cutting-edge solutions to its clientele.

Design Considerations for Precision Plastic Products

Design plays a pivotal role in achieving precision and functionality in plastic products. Louis Machine employs a holistic approach to design, considering various factors to optimize product performance and manufacturability.

3.1 Mold Design

Mold design is critical for achieving precise dimensions and surface finishes in plastic products. Precision plastic products manufacturer like Louis Machine employs advanced CAD/CAM technologies to design molds that ensure consistency and repeatability in production.

3.2 Part Geometry

Optimizing part geometry is essential for minimizing warpage, sink marks, and other defects during the molding process. Louis Machine collaborates closely with clients to refine part geometry for optimal performance and cost-effectiveness.

3.3 Tolerances

Tight tolerances are imperative for precision plastic products, especially in industries like aerospace and medical, where accuracy is non-negotiable. Louis Machine meticulously adheres to specified tolerances, employing advanced metrology tools to validate component dimensions.

3.4 Draft Angles

Draft angles facilitate easy ejection of molded parts from the mold, reducing the risk of damage and ensuring uniformity in production. Louis Machine carefully designs draft angles to streamline the molding process and enhance productivity.

Exploring the Injection Molding Process

Injection molding stands as a cornerstone of precision plastic product manufacturing, offering unparalleled efficiency, versatility, and precision. Precision plastic products manufacturer like Louis Machine harnesses the power of injection molding to create intricate plastic components with utmost accuracy and consistency.

5.1 Role in Manufacturing Precision Plastic Products

Injection molding plays a pivotal role in fabricating precision plastic products by injecting molten plastic material into a mold cavity under high pressure. This process enables the production of complex shapes with tight tolerances, meeting the stringent requirements of various industries.

5.2 Steps Involved in Injection Molding

The injection molding process comprises several stages, including mold design, material preparation, injection, cooling, and ejection. Louis Machine meticulously executes each step, leveraging advanced technologies and expertise to ensure optimal results.

5.3 Techniques for Precision and Consistency

Achieving precision and consistency in injection molding requires attention to detail and adherence to best practices. Louis Machine employs techniques such as scientific molding, mold flow analysis, and process optimization to control variables and enhance product quality.

Quality Control and Assurance in Precision Plastic Manufacturing

Ensuring the quality and precision of plastic products is paramount for Louis Machine, driving the implementation of robust quality control measures throughout the manufacturing process.

6.1 Dimensional Inspection

Dimensional inspection involves the use of precise measurement tools and techniques to verify product dimensions and tolerances. Louis Machine employs advanced metrology equipment, such as coordinate measuring machines (CMMs) and optical scanners, to validate component dimensions with micron-level accuracy.

6.2 Surface Finish Evaluation

Surface finish evaluation is crucial for assessing the cosmetic appearance and functionality of plastic products. Precision plastic products manufacturer like Louis Machine conducts thorough surface finish inspections using visual inspection methods and surface profilometers to ensure products meet aesthetic and performance standards.

6.3 Material Testing

Material testing is essential for verifying the mechanical properties, chemical resistance, and durability of plastic materials. Louis Machine collaborates with accredited laboratories to perform comprehensive material testing, including tensile testing, impact testing, and thermal analysis, to validate material performance and integrity.

Applications and Industries Utilizing Precision Plastic Products

Louis Machine’s precision plastic products find applications across diverse industries, catering to the unique needs and requirements of each sector.

7.1 Automotive Industry

In the automotive industry, precision plastic products are used in interior and exterior components, such as dashboards, door panels, and grilles. Louis Machine supplies automotive manufacturers with precision-engineered parts that meet stringent quality and performance standards.

7.2 Medical Sector

In the medical sector, precision plastic products are integral to devices and equipment used in diagnostics, treatment, and patient care. Louis Machine manufactures medical-grade components, including surgical instruments, implantable devices, and diagnostic tools, adhering to strict regulatory requirements and quality standards.

7.3 Electronics Sector

In the electronics sector, precision plastic products play a vital role in housing electronic components, connectors, and enclosures. Louis Machine produces custom-designed plastic parts for electronic devices, ensuring optimal functionality, durability, and reliability in demanding electronic applications.

7.4 Consumer Goods Market

In the consumer goods market, precision plastic products enhance the aesthetics, functionality, and user experience of various products, including household appliances, toys, and personal care products. Louis Machine collaborates with consumer goods manufacturers to develop innovative plastic solutions that meet market demands and consumer preferences.

Conclusion

In the realm of precision plastic products manufacturing, Precision plastic products manufacturer like Louis Machine stands as a beacon of excellence, combining expertise, innovation, and quality craftsmanship. Through meticulous attention to detail, advanced technologies, and a commitment to customer satisfaction, Louis Machine continues to redefine the standards of precision engineering in the industry. With a relentless pursuit of perfection, Louis Machine remains at the forefront of innovation, shaping the future of precision plastic manufacturing.