Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

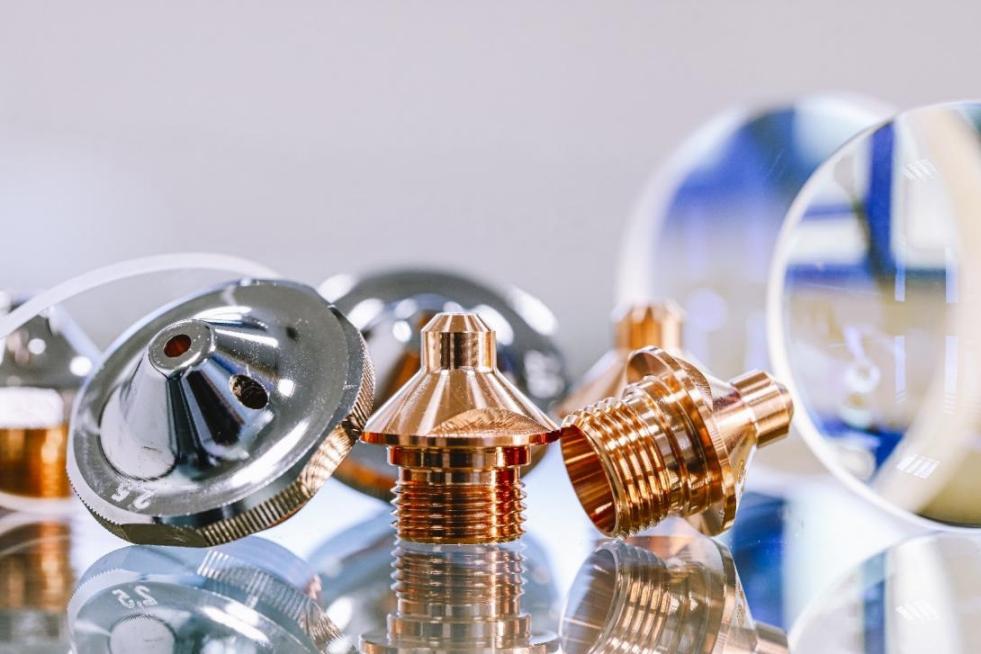

Subcontracting Spare Parts with Louis Machine’s Precision Mold Design

Louis Machine stands as a distinguished entity in the realm of professional machining, celebrated for its adeptness in precision mold design and an array of manufacturing services, including plastic injection molding, metal hardware processing, and automotive parts production. Bolstered by a team of seasoned technical experts and management professionals, Louis Machine pledges a holistic one-stop solution covering design, manufacturing, injection molding or die casting, and the mass processing of parts. In the manufacturing industry, subcontracting emerges as a pivotal strategy, enabling companies to enhance efficiency, focus on core competencies, and access specialized capabilities. Precision mold design plays a crucial role in this context, especially in subcontracting spare parts, offering unparalleled accuracy and quality, which are vital for the success and reliability of the manufacturing process.

Precision Mold Design’s Crucial Role in Manufacturing

The Essence and Significance of Precision Mold Design

At the core of manufacturing, especially for parts requiring utmost accuracy, lies precision mold design. This method involves creating molds that yield parts with exact tolerances and intricate shapes. Its importance is profound, as it greatly impacts the produced parts’ quality, uniformity, and function. Efficient production, minimized waste, and less need for additional processing are the hallmarks of a thoughtfully designed mold, making it a fundamental aspect of contemporary manufacturing practices.

Advantages of Precision Molds in Spare Parts Production

The application of precision molds in spare parts production brings forth numerous benefits. Consistency in quality and dimensions is a prime advantage, crucial for parts needing precise integration into larger assemblies. Additionally, the reduction in defects brought about by precision molds lowers the costs tied to waste and redoing work. These molds are also built to last, enabling the mass production of parts throughout their lifecycle. This not only proves to be cost-effective for manufacturers but also ensures the spare parts’ prompt availability.

Overview of the Subcontracting Process

Key Steps for Subcontracting Spare Parts to a Third Party

The process to subcontract spare parts production unfolds through well-defined steps, beginning with identifying needs and selecting a suitable partner like Louis Machine. This process entails:

- Defining Specifications: Detailed specification of the spare parts including size, tolerance levels, material, and volume expectations.

- Selecting a Vendor: Choosing a subcontractor based on their expertise, capabilities, and project fit.

- Negotiating and Agreeing: Getting quotations, discussing terms, and concluding a contract.

- Design and Prototype Creation: Working together on the mold design and, if needed, producing prototypes.

- Starting Production: Kicking off the manufacturing phase following design validation.

- Ensuring Quality and Delivery: Verifying the parts’ quality standards before dispatch.

Louis Machine’s Role in Spare Parts Subcontracting

Louis Machine integrates smoothly into this framework by providing comprehensive solutions from mold design to spare parts production. By fostering collaboration, the company aligns closely with client needs, ensuring optimized processes for quality, efficiency, and affordability. Louis Machine’s prowess in precision mold design, alongside its full-scale manufacturing capabilities, positions it as a top choice for subcontracting spare parts production.

Considerations When Subcontracting with Louis Machine

Ensuring Quality and Control

Louis Machine places a strong emphasis on quality at every operation level. Adherence to the ISO 9001:2015 standards affirms that every product, from conception to completion, meets stringent quality checks. This dedication guarantees that clients receive parts that not only meet but potentially exceed their quality expectations.

Timeliness and Meeting Deadlines

Recognized for efficient time management and punctuality, Louis Machine’s proprietary instant quoting system provides swift and precise project estimates, giving clients a clear timeline perspective right from the start. This commitment, combined with efficient production practices, ensures the on-time delivery of custom parts, catering to the pressing needs of its clientele.

Cost Consideration and Budgeting

For subcontracting endeavors, financial viability remains a key factor. The instant quoting system by Louis Machine offers clear, competitive pricing, empowering clients with the information needed for sound financial planning. This approach, together with streamlined production, promises a valuable investment, striking a balance between quality, time, and expenditure.

Communication and Coordination

Successful subcontracting projects depend heavily on robust communication and coordination. Louis Machine champions open, ongoing dialogue with its clients, ensuring alignment throughout the project duration. This cooperative stance promotes efficient project management, timely modifications if needed, and ultimately, the delivery of superior quality spare parts.

Encountering and Addressing Subcontracting Hurdles

The journey of subcontracting precision components is fraught with obstacles, such as ensuring unwavering accuracy, consistent quality, logistical efficiency, and effective communication among stakeholders. These hurdles can significantly influence the subcontracting endeavor’s cost-effectiveness and overall productivity.

Louis Machine’s Strategic Approaches to Overcome Obstacles

To effectively tackle these challenges, Louis Machine has devised and implemented a multifaceted strategy:

- Rigorous Quality Assurance: Adopting stringent quality control protocols throughout the production lifecycle ensures each component meets the highest precision and consistency standards.

- Enhanced Communication Tactics: Leveraging cutting-edge communication and project management technologies keeps every participant well-informed and actively involved from start to finish.

- Optimizing the Supply Chain: Crafting resilient supply chain strategies to alleviate logistical complexities and guarantee the punctual arrival of components.

- Ongoing Team Empowerment: Prioritizing continuous education and skill enhancement for its workforce to stay abreast of evolving industry benchmarks and technological advancements.

Illustrative Success Stories in Subcontracting

A standout instance involved engineering a component demanding extreme precision. Through its superior grinding and CNC capabilities, Louis Machine met the exacting precision needed, addressing substantial technical hurdles to fulfill the client’s specific demands.

Benefits of Partnering with Louis Machine for Subcontracting

Mastery in Precision Mold Design

Louis Machine’s team showcases profound expertise in precision mold design, achieving exceptional accuracies, such as sub-micron level grinding accuracy and CNC processing precision of +/- 0.002mm, among others. This expertise is foundational to the company’s esteemed status in mold design and manufacturing.

Assured Quality and Client Satisfaction

Diligent focus on detail and stringent quality measures culminate in the utmost product quality, fostering high client satisfaction levels. Louis Machine’s unwavering commitment to quality is pivotal to forging successful and dependable subcontracting alliances.

Operational Efficiency and Cost Reduction

Through streamlined manufacturing processes and expert technical support, Louis Machine delivers operational efficiencies and cost advantages to its partners. This optimization translates into shorter production cycles and cost savings, aligning with global market demands.

Sustaining a Productive Subcontracting Partnership

Engaging in a subcontracting partnership with Louis Machine presents enduring advantages like consistent quality, reliability, and a deep understanding of precision manufacturing intricacies. This partnership is geared towards mutual growth and innovation, propelling success in a competitive landscape.

Future Directions in Precision Mold Design and Subcontracting

Impact of Technological Progress

Precision mold design and manufacturing are on the cusp of transformation, driven by advancements in CNC machining, 3D printing, and automation. These innovations promise to refine precision, curtail production timelines, and reduce expenses, charting the future course of mold design and manufacturing.

Adapting to Shifting Industry Standards

In response to evolving industry norms, Louis Machine proactively integrates the latest technological innovations and practices. This forward-thinking approach ensures the company not only meets but surpasses contemporary quality and efficiency standards, reinforcing its industry leadership.

Emerging Opportunities for Subcontracting Ventures

The dynamic landscape of technological evolution and Louis Machine’s dedication to excellence unveil new avenues for businesses contemplating subcontracting for spare parts production. Equipped with unmatched expertise and a visionary outlook, Louis Machine is poised to address future industry demands, offering its clients a competitive edge in precision manufacturing.

CONCLUSION

Subcontracting spare parts with Louis Machine’s precision mold design encapsulates a journey towards unparalleled quality, efficiency, and innovation. By overcoming the inherent challenges of precision parts manufacturing through strategic solutions, Louis Machine ensures each component meets the highest standards of accuracy and consistency. Their expertise in precision mold design, coupled with a commitment to quality assurance and client satisfaction, positions them as a leader in the subcontracting domain. The future of subcontracting, bolstered by technological advancements and evolving industry standards, promises even greater opportunities for businesses looking to leverage Louis Machine’s capabilities. In essence, choosing Louis Machine for subcontracting spare parts means opting for a partnership that values excellence, anticipates future trends, and delivers on the promise of quality and reliability.