Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

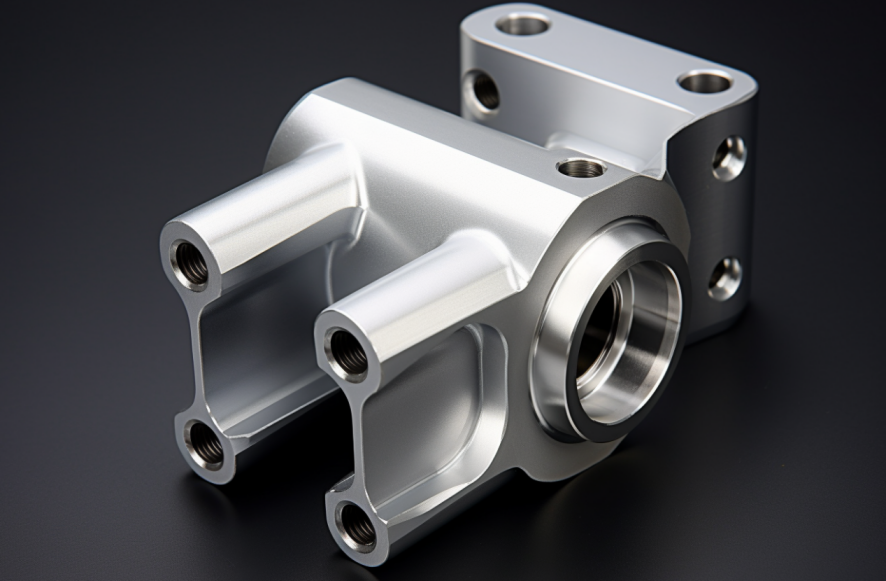

Mastering Precision: Solutions of Turning Mill Production

Louis Machine’s turning mill production service exemplifies a blend of advanced technology, unparalleled expertise, and customizable solutions. Whether it’s leveraging cutting-edge machinery, collaborating on bespoke designs, or ensuring stringent quality control, Louis Machine sets the standard for excellence in precision engineering. For industries seeking a trusted partner in turning mill production, Louis Machine stands ready to deliver innovative solutions that drive success and exceed expectations.

Introduction

In the realm of modern manufacturing, turning mill production stands as a cornerstone of precision engineering and component manufacturing. This sophisticated process combines the capabilities of turning and milling into a single operation, allowing for the creation of complex parts with utmost accuracy and efficiency. As industries continue to evolve, the demand for turning mill production services has grown exponentially, driven by the need for high-quality, custom-engineered components across various sectors.

Staying abreast of the latest trends in turning mill production is crucial for manufacturers aiming to maintain a competitive edge in the market. Technological advancements play a pivotal role in shaping the landscape of this industry, influencing everything from operational efficiencies to product quality and innovation.

Latest Trends in Turning Mill Production

Integration of Advanced Automation and Robotics

One of the most notable trends in turning mill production is the increasing integration of advanced automation and robotics. Automation streamlines manufacturing processes by reducing human intervention, thereby enhancing precision, consistency, and throughput. Robotics, equipped with AI-driven capabilities, can perform complex tasks with unparalleled speed and accuracy, revolutionizing production capabilities.

Louis Machine, a leading turning mill production service provider, has embraced automation to optimize their operations. By leveraging state-of-the-art robotic systems, they ensure not only efficiency but also the ability to handle intricate designs and tight tolerances demanded by modern industries.

AI and Machine Learning for Predictive Maintenance and Optimization

AI and machine learning have significantly enhanced predictive maintenance and optimization in turning mill production. These technologies analyze vast amounts of data in real-time to predict potential equipment failures, optimize tool paths for maximum efficiency, and improve overall process reliability. Such capabilities minimize downtime, reduce operational costs, and extend equipment lifespan.

Louis Machine incorporates AI-driven analytics into their production processes, enabling proactive maintenance and continuous improvement. This proactive approach ensures consistent quality and reliability in every component they manufacture.

Sustainability Practices in Manufacturing Processes

Sustainability is increasingly becoming a focal point in manufacturing operations, including turning mill production. Companies like Louis Machine are adopting eco-friendly practices such as efficient use of resources, recycling of materials, and reducing carbon footprints. Sustainable manufacturing not only aligns with global environmental goals but also enhances brand reputation and operational efficiency.

Louis Machine integrates sustainable practices throughout their production cycle, from sourcing materials to optimizing energy consumption and waste management. Their commitment to sustainability ensures that clients receive not only high-quality components but also environmentally responsible manufacturing solutions.

Meeting Diverse Project Needs

Louis Machine excels in meeting diverse project requirements across various industries, demonstrating versatility and expertise in turning mill production.

UAV Parts: Lightweight Materials, Precision, and Durability

In the aerospace and defense sectors, UAVs (Unmanned Aerial Vehicles) require components that are lightweight yet durable, capable of withstanding harsh conditions while maintaining precision. Louis Machine utilizes advanced materials and precise machining techniques to deliver UAV parts that meet stringent aerospace standards.

Smart Ring: High Precision and Intricate Design Capabilities

In the consumer electronics industry, smart rings demand high precision and intricate design capabilities. These wearable devices require components that are not only functional but also aesthetically appealing and comfortable to wear. Louis Machine’s advanced CNC (Computer Numerical Control) capabilities and meticulous attention to detail ensure the production of smart ring components that meet exacting specifications.

Precision Needle: Tight Tolerances and Material Suitability

Medical devices such as precision needles necessitate extremely tight tolerances and specific material properties to ensure safety and effectiveness. Louis Machine specializes in machining precision components for medical applications, utilizing medical-grade materials and stringent quality control measures to produce needles that meet the highest standards of accuracy and performance.

Advanced Technology: Cutting-Edge Machinery and Software

Louis Machine integrates cutting-edge technology into its production processes, ensuring precision and efficiency. Their state-of-the-art CNC machines are equipped with advanced tooling capabilities, enabling complex machining operations with high repeatability and accuracy. Additionally, they utilize sophisticated CAD/CAM software for optimal tool path generation and simulation, minimizing production lead times and maximizing output quality.

The investment in advanced technology positions Louis Machine as a leader in the industry, capable of delivering intricate components that meet the most stringent specifications across diverse sectors.

Expertise and Experience: Delivering High-Quality Components

With decades of experience in turning mill production, Louis Machine has built a solid reputation for delivering high-quality components. Their team of skilled engineers and technicians possesses deep expertise in machining techniques, materials science, and industry-specific requirements. This extensive knowledge base allows Louis Machine to tackle complex challenges and consistently exceed client expectations.

Louis Machine’s track record speaks for itself, with a portfolio of successful projects in aerospace, automotive, medical devices, and more. Their dedication to craftsmanship and attention to detail ensure that every component manufactured meets the highest standards of performance and reliability.

Customization Options: Adapting to Specific Project Requirements

One of the key advantages of choosing Louis Machine is their flexibility in customization. They understand that every project is unique, with its own set of requirements and challenges. Louis Machine collaborates closely with clients to tailor their turning mill production services to exact specifications.

Whether it’s adjusting material choices, refining design elements, or meeting specific dimensional tolerances, Louis Machine thrives on solving complex engineering problems through customized solutions. This adaptability not only enhances product functionality but also accelerates time-to-market for clients, giving them a competitive edge in their respective industries.

Customizing Your Turning Mill Production Service

Louis Machine provides a seamless process for customizing turning mill production services, ensuring precision and quality from concept to completion.

Initial Consultation and Project Assessment Process

The journey begins with an in-depth consultation and project assessment. Louis Machine’s team collaborates closely with clients to understand their unique requirements, technical specifications, and project goals. This initial phase lays the foundation for a successful partnership, fostering clear communication and alignment on deliverables.

During this stage, Louis Machine leverages its expertise to offer valuable insights and recommendations, ensuring that all aspects of the project—from design feasibility to production scalability—are thoroughly evaluated and optimized.

Collaborative Design Phase and Prototyping

Once the project parameters are defined, Louis Machine embarks on the collaborative design phase. Their engineers work closely with clients to translate concepts into detailed CAD models and technical drawings. This iterative process allows for refinement and validation of design elements, ensuring that the final product not only meets but exceeds expectations.

Prototyping is a critical step in Louis Machine’s approach to customization. Using rapid prototyping techniques and advanced manufacturing processes, they produce functional prototypes for testing and validation. This hands-on approach enables early identification of potential challenges and opportunities for enhancement, ultimately leading to a more robust final product.

Quality Control Measures and Testing Procedures

Quality is paramount at Louis Machine, underpinned by rigorous quality control measures and testing procedures throughout the production cycle. Every component undergoes comprehensive inspection using advanced metrology equipment to verify dimensional accuracy, surface finish, and material integrity.

Louis Machine adheres to industry standards and client-specific requirements, ensuring that all manufactured parts meet or exceed regulatory guidelines and performance benchmarks. From first article inspection to final acceptance testing, their commitment to quality assurance instills confidence in the reliability and consistency of their products.

Conclusion

In conclusion, turning mill production services offered by Louis Machine exemplify the pinnacle of modern manufacturing excellence. By embracing technological innovation, adhering to sustainable practices, and meeting diverse project needs across industries, Louis Machine continues to redefine what is possible in precision engineering. Whether it’s aerospace, consumer electronics, medical devices, or beyond, Louis Machine stands as a trusted partner in delivering bespoke solutions that drive innovation and efficiency. For manufacturers seeking uncompromising quality and reliability in turning mill production, Louis Machine remains a beacon of excellence in the field.