Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Essential Guide to UAV Parts Machining

UAV parts machining is a specialized process crucial for enhancing the performance, durability, and functionality of unmanned aerial vehicles (UAVs). It involves the precise fabrication of custom components tailored to specific operational requirements and environmental conditions. Machining techniques such as CNC machining enable manufacturers to achieve high levels of accuracy and consistency in producing parts from a wide range of materials, including lightweight composites and high-grade alloys.

Each part undergoes meticulous design, programming, and quality assurance processes to ensure it meets stringent aerospace standards. The customization of UAV parts through machining not only improves flight dynamics, payload capacity, and operational efficiency but also supports innovative advancements in UAV technology across various sectors, from agriculture and surveillance to logistics and research.

UAV Parts: Driving Innovation in the Aerospace Industry

Introduction to UAV Industry Trends

In recent years, the UAV (Unmanned Aerial Vehicle) industry has experienced rapid growth and technological advancement, revolutionizing sectors from agriculture to defense. The latest trends showcase a shift towards smaller, more agile UAVs capable of autonomous operations and enhanced payload capacities. Technological advancements in battery life, artificial intelligence, and sensor integration have propelled UAVs beyond traditional applications, opening new opportunities in surveillance, logistics, and environmental monitoring.

Technological Advancements and Market Growth

Advancements in UAV technology have led to lighter, more durable materials, such as carbon fiber composites and lightweight alloys, which improve flight performance and endurance. Miniaturization of components, including sensors and processors, has enabled UAVs to collect and process vast amounts of data in real-time, enhancing their utility in diverse environments. Market growth is driven by increasing investments in research and development, as well as expanding regulatory frameworks that facilitate commercial UAV operations globally.

Benefits of Custom UAV Parts

Custom UAV parts play a pivotal role in advancing drone capabilities. By tailoring components to specific operational requirements, manufacturers can optimize UAV performance in terms of speed, maneuverability, and payload capacity. Customization also allows for integration of proprietary technologies and sensors, enhancing data collection accuracy and operational efficiency. Moreover, bespoke parts can reduce overall weight and improve aerodynamics, crucial for extending flight durations and increasing mission success rates in challenging environments.

How Custom Parts Contribute to Innovation and Efficiency

The ability to customize UAV parts fosters innovation by pushing the boundaries of what UAVs can achieve. For instance, specialized payloads for agriculture can include multispectral cameras for precise crop monitoring or spraying systems for targeted pesticide application. In the logistics sector, custom parts enable UAVs to carry heavier payloads over longer distances, optimizing delivery routes and reducing operational costs. Furthermore, customized components facilitate rapid prototyping and iterative design improvements, accelerating time-to-market for new UAV models and functionalities.

Partnership Opportunities with Louis Machine

Louis Machine stands out as a premier supplier specializing in custom UAV parts machining. With a proven track record in precision engineering and a commitment to innovation, Louis Machine offers UAV companies a strategic partnership for developing high-performance drone components. By leveraging state-of-the-art CNC machining capabilities and industry expertise, Louis Machine ensures the production of complex, high-quality parts that meet stringent aerospace standards.

Introduction to Louis Machine

Louis Machine is renowned for its ability to collaborate closely with UAV manufacturers, providing tailored solutions that align with specific project requirements. Whether it’s prototyping a new drone design or scaling production for commercial deployment, Louis Machine’s team of engineers and technicians excel in delivering precision-engineered components that enhance UAV performance and reliability. This partnership approach enables UAV companies to focus on core competencies while benefiting from Louis Machine’s manufacturing expertise and commitment to quality.

Benefits of Partnering with a Specialized Machining Service Provider

Partnering with Louis Machine offers several strategic advantages. Firstly, UAV manufacturers gain access to advanced machining technologies and materials selection expertise, ensuring optimal component design and performance. Secondly, Louis Machine’s efficient production processes and quality assurance measures guarantee reliable and timely delivery of custom UAV parts, crucial for meeting project deadlines and customer expectations. Lastly, collaborative partnerships with Louis Machine foster innovation through continuous improvement and iterative design refinement, resulting in UAVs that set new benchmarks in performance and reliability.

Mastering UAV Parts: A Journey Through Custom Machining with Louis Machine

The Process of Custom UAV Parts Machining

Custom UAV parts are crucial in enhancing the performance, durability, and functionality of unmanned aerial vehicles. Louis Machine specializes in this field, offering a comprehensive approach to machining bespoke components tailored to specific UAV requirements. Here’s a detailed look at the step-by-step process of custom UAV parts machining.

Initial Consultation and Design Review

The journey begins with an in-depth consultation, where Louis Machine’s engineers collaborate with UAV companies to understand their unique needs and objectives. This phase involves discussing the UAV’s intended application, performance specifications, and any particular challenges the design might face. Through detailed discussions and brainstorming sessions, the team at Louis Machine ensures that every aspect of the component design aligns with the UAV’s mission and operational goals.

Material Selection and Procurement

Once the design parameters are defined, the focus shifts to selecting the appropriate materials. Louis Machine offers expertise in a wide range of materials, from lightweight composites to high-strength alloys, ensuring that each part is optimized for its specific application. The selection process considers factors such as weight, strength, durability, and environmental resistance. Louis Machine’s extensive network of suppliers ensures timely procurement of high-quality materials, enabling a smooth transition to the next stages of machining.

CAD/CAM Design and Programming

With the design specifications and materials in place, the next step is CAD/CAM design and programming. Louis Machine utilizes advanced CAD software to create detailed 3D models of the UAV parts, allowing for precise visualization and modification. These models are then translated into CNC machine code through CAM software, ensuring that the machining process is highly accurate and efficient. This stage is crucial for identifying potential design improvements and ensuring that the final product meets all performance and quality standards.

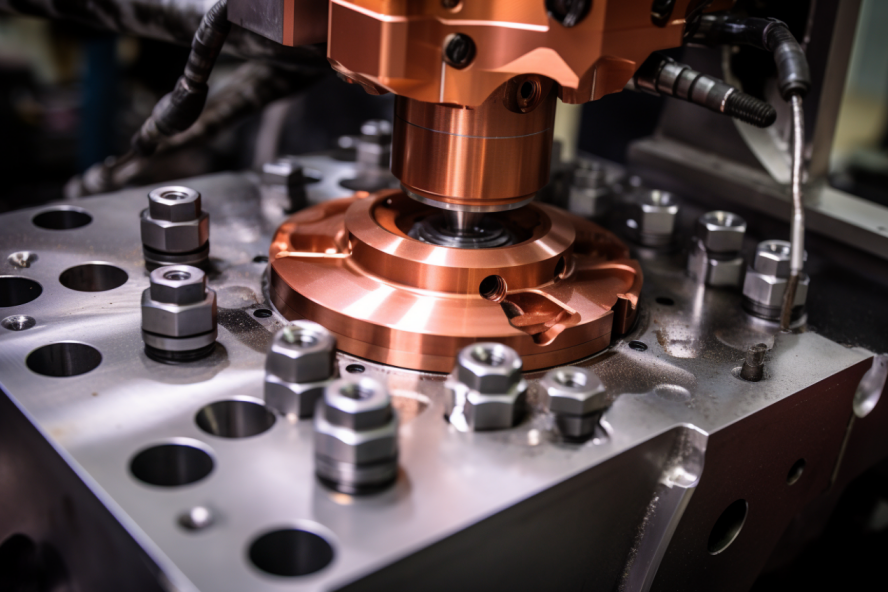

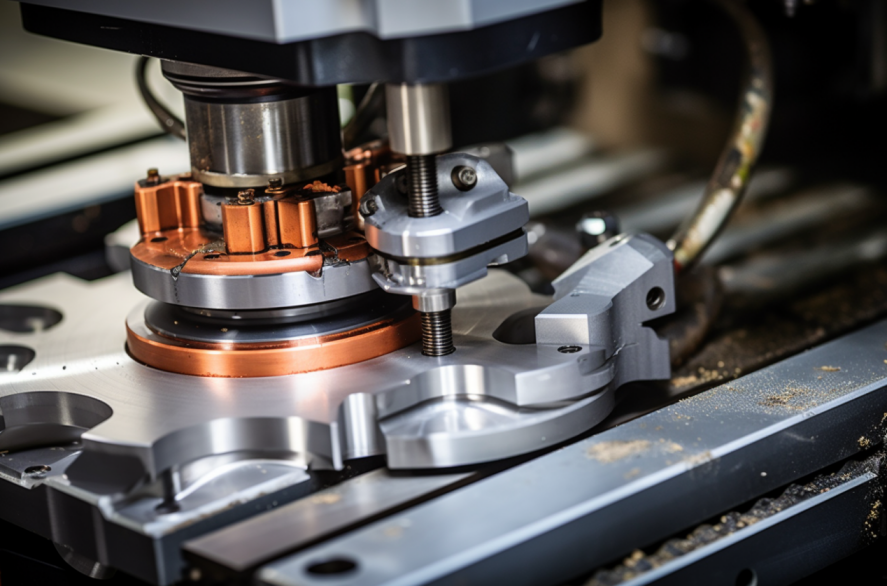

Precision Machining and Quality Assurance

The machining process at Louis Machine is carried out using state-of-the-art CNC machinery, capable of producing components with exceptional precision and consistency. Skilled machinists oversee the process, ensuring that each part is fabricated to exact specifications. Quality assurance is a top priority, with rigorous testing and inspection at every stage of production. This includes dimensional checks, surface finish assessments, and material integrity tests, ensuring that the final parts meet or exceed industry standards.

Showcasing Success: Case Studies and Examples

Louis Machine’s expertise in custom UAV parts machining is demonstrated through numerous successful collaborations with UAV companies. Here are a few notable examples:

Enhancing Surveillance Capabilities

In one project, Louis Machine worked with a leading UAV manufacturer to develop custom gimbal mounts for high-resolution cameras. By optimizing weight distribution and anti-seismic design. Louis Machine significantly improves the stability and image quality of surveillance drones. This enhancement enabled the UAVs to capture clearer, more detailed footage, enhancing their effectiveness in security and surveillance operations.

Advancing Agricultural Drones

Another notable project involved the development of specialized spray nozzles for agricultural UAVs. Louis Machine’s team designed custom nozzles with adjustable spray patterns and flow rates, tailored to the specific needs of different crops and spraying techniques. This innovation increased the efficiency of pesticide and fertilizer application, reducing waste and improving crop yields. The custom parts not only enhanced the UAV’s operational capabilities but also contributed to more sustainable agricultural practices.

Pushing the Boundaries in Research Drones

Louis Machine also partnered with a research institution to develop custom lightweight frames for high-altitude research UAVs. These frames were designed to withstand extreme weather conditions and high-altitude pressures while maintaining structural integrity. The collaboration resulted in a series of drones capable of conducting advanced atmospheric research. Provides valuable data for climate science and environmental monitoring.

How to Customize Your UAV Parts with Louis Machine

For UAV companies or developers looking to create bespoke parts, Louis Machine provides a seamless process from concept to final production. Here’s a guide to help you get started:

Identifying Specific Needs and Requirements

The first step is to clearly define your UAV’s operational requirements. This includes specifying the UAV’s mission objectives, environmental conditions, and performance metrics. Understanding these parameters helps in identifying the exact specifications needed for your custom parts. Louis Machine’s team works closely with you to document these requirements, ensuring that every detail is considered in the design process.

Choosing the Right Materials and Manufacturing Processes

Selecting the right materials and manufacturing processes is crucial for the performance and longevity of your UAV parts. Louis Machine’s experts will guide you on the best material for your application. Whether you require lightweight composites, high-strength alloys or other advanced materials. They will also advise on the most appropriate manufacturing technology. From CNC machining and 3D printing to injection molding, we ensure your part performs and is cost-effective.

Working with Louis Machine: Consultation, Design Iterations, and Final Production

Throughout the design and production process, Louis Machine maintains close communication with you, providing regular updates and seeking your feedback. The iterative design process allows for continuous refinement, ensuring that the final parts meet all specifications and performance criteria. Once the design is finalized, Louis Machine proceeds with production, maintaining strict quality control and adhering to industry standards. The result is a set of custom UAV parts that enhance your drone’s capabilities and reliability, giving you a competitive edge in the UAV market.

Conclusion

In conclusion, the UAV industry continues to evolve rapidly, driven by technological advancements and innovative applications across various sectors. Custom UAV parts are integral to this evolution, enabling manufacturers to push boundaries and unlock new capabilities in drone technology. Partnering with Louis Machine enables UAV companies to fully exploit the potential of custom part machining. Ensuring their UAVs achieve optimal performance and reliability in dynamic operating environments.